Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

What are the specific steps for reinforcing bridge cracks with carbon fiber?

The specific steps for reinforcing bridge cracks by pasting carbon fiber are as follows:

Construction preparation:

Plan formulation: Based on the specific situation and design requirements of the bridge, develop a detailed construction plan and schedule for pasting carbon fiber cloth.

Material preparation: Prepare the required carbon fiber sheets, matching resin adhesives (primer, impregnating adhesive, surface adhesive, etc.), rollers, scrapers, scrapers, angle grinders, hair dryers, sandpaper, wire brushes, alcohol and other tools and materials, and ensure that the quality and performance of the materials meet the requirements.

On site cleaning: Clean up the construction site, remove obstacles and debris on the bridge, and ensure that the construction area is clean and tidy.

Safety measures: Set up safety warning signs in the construction area, equip necessary safety protection equipment, and ensure the safety of construction personnel.

Substrate processing:

Polishing: Use tools such as angle grinders and sandpaper to polish the concrete surface of the bridge that needs to be reinforced, removing surface floating slurry, oil stains, loose layers, carbonization layers, etc., until a solid new concrete surface is exposed. The polishing depth is generally 0.3-0.5mm.

Rust removal: If there are exposed steel bars in the concrete structure, rust removal treatment should be carried out on the steel bars to prevent them from rusting and affecting the reinforcement effect.

Crack treatment: For cracks on bridges, the first step is to clean them, remove dust, debris, etc. from the cracks, and then treat them according to their width and depth. For cracks with a width less than 0.2mm, epoxy resin can be directly used for sealing; For cracks with a width greater than 0.2mm, grouting treatment should be carried out first to fill the cracks fully before sealing.

Rounding treatment: Polish the corners of the bridge structure into rounded corners with a radius of not less than 20mm to avoid stress concentration and ensure the bonding effect of carbon fiber cloth.

Base cleaning:

Remove floating debris: Use a wire brush and compressed air to clean the floating debris on the polished concrete surface, ensuring a smooth and clean surface.

Wipe alcohol: Use anhydrous alcohol to wipe the surface of concrete, remove residual oil and impurities, and ensure the adhesion between carbon fiber cloth and concrete.

Apply primer:

Bottom glue preparation: According to the requirements of the resin glue product manual, accurately weigh the main agent and curing agent of the bottom glue, pour them into a clean container, and stir evenly with a mixer. Please note that the mixing time should not be too long or too short to avoid affecting the performance of the base adhesive.

Applying primer: Use a roller or brush to evenly apply the prepared primer onto the concrete surface, with a moderate thickness to avoid being too thick or too thin. After painting, let the base adhesive air dry naturally. After the base adhesive fingers touch dry (usually taking several hours), the next step of construction can be carried out.

Adhesive surface repair (if necessary): If there are concave or uneven areas on the adhesive surface, it will affect the bonding effect of the carbon fiber cloth, and leveling glue needs to be used for repair. Apply leveling glue to the concave area, scrape it flat with a tool, and wait for the leveling glue to cure before sticking the carbon fiber cloth.

Apply carbon fiber:

Cutting carbon fiber: Cut the carbon fiber cloth into appropriate sizes according to design requirements and actual on-site conditions. When cutting, pay attention to maintaining the flatness of the carbon fiber cloth to avoid wrinkles or distortions.

Applying impregnating adhesive: Prepare impregnating adhesive in proportion, stir evenly, and use a roller or brush to evenly apply impregnating adhesive to the area where carbon fiber cloth needs to be pasted.

Paste carbon fiber: Paste the cut carbon fiber cloth in the direction required by the design on the area coated with impregnating adhesive, and use a scraper or defoaming roller to drive out the air under the carbon fiber cloth from one side to the other, so that the carbon fiber cloth is tightly adhered to the surface of the concrete. When pasting, pay attention to maintaining the flatness and tension of the carbon fiber cloth to avoid phenomena such as hollowing and foaming. If multiple layers of bonding are required, the impregnated adhesive on the surface of the previous layer of carbon fiber cloth should be dried before proceeding to the next layer of bonding.

Cover protection treatment:

Coating adhesive: Apply a layer of adhesive evenly on the surface of the pasted carbon fiber cloth to protect it and improve its durability.

Sprinkle small stones (optional): If you need to increase the wear resistance and slip resistance of carbon fiber cloth, you can evenly sprinkle a layer of small stones with a particle size generally not exceeding 10mm before the adhesive is dry.

Natural maintenance: Let the carbon fiber cloth be maintained in a natural environment for 1-2 weeks, during which it should be avoided from being impacted or disturbed by external forces.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

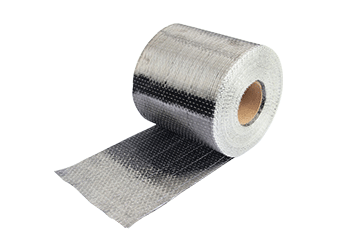

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Low viscosity, strong penetration carbon fiber primer for reinforced concrete surface to enhace the defect part

Good thixotropy carbon fiber leveling adhesive for concrete surface repairing