Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fibre reinforced polymer (CFRP) strengthening has emerged as a leading-edge solution for enhancing the structural performance, durability, and load-bearing capacity of concrete structures.

Carbon fibre reinforced polymer (CFRP) strengthening has emerged as a leading-edge solution for enhancing the structural performance, durability, and load-bearing capacity of concrete structures. This advanced retrofitting technique leverages the exceptional mechanical properties of carbon fibres combined with high-performance polymer matrices to provide superior reinforcement compared to traditional steel-based methods.

The following sections present a detailed technical discussion on material characteristics, strengthening methodologies, design considerations, and quality assurance protocols for CFRP applications in concrete structures.

1. Material Properties and Performance Advantages

Carbon fibre reinforced polymers exhibit a unique combination of mechanical and physical properties that make them ideally suited for structural strengthening applications:

Ultra-High Tensile Strength: CFRP materials typically demonstrate tensile strengths ranging from 3,000 MPa to 7,000 MPa, significantly exceeding conventional steel reinforcement (400–600 MPa). This enables substantial increases in load capacity without adding excessive weight.

High Modulus of Elasticity: The elastic modulus of CFRP ranges between 200 GPa and 700 GPa, ensuring efficient stress transfer and minimizing interfacial shear stresses that could lead to premature delamination.

Lightweight Nature: With a density of approximately 1.6 g/cm³, CFRP imposes negligible additional dead load on the structure, making it particularly advantageous for seismic retrofitting and long-span applications.

Corrosion Resistance: Unlike steel reinforcement, CFRP is immune to chloride-induced corrosion, alkali-silica reaction (ASR), and other electrochemical degradation mechanisms, ensuring long-term durability in harsh environments.

Low Thermal Expansion Coefficient: CFRP exhibits a coefficient of thermal expansion (0.6–2.3 × 10⁻⁶/°C) closely matched to concrete (~10 × 10⁻⁶/°C), reducing thermal stress-induced debonding risks.

Fatigue Resistance: CFRP demonstrates superior fatigue performance under cyclic loading, making it ideal for bridges, industrial floors, and other dynamically loaded structures.

2. Strengthening Methodologies and System Configurations

CFRP strengthening systems can be implemented through several well-established techniques, each optimized for specific structural requirements:

2.1 Externally Bonded Reinforcement (EBR) Systems

Wet Layup Method: Unidirectional carbon fibre sheets are impregnated with epoxy resin and manually applied to prepared concrete surfaces, conforming to complex geometries.

Precured CFRP Laminates: Factory-manufactured pultruded CFRP plates are adhesively bonded to the substrate, offering higher stiffness and controlled thickness tolerances.

2.2 Near-Surface Mounted (NSM) Technique

CFRP strips or bars are embedded into precision-cut grooves in the concrete cover and secured with high-strength epoxy paste.

Provides enhanced bond performance and protection against mechanical damage, fire, and environmental exposure.

2.3 Hybrid Strengthening Systems

Combines externally bonded CFRP with NSM or post-tensioned CFRP tendons for synergistic load-sharing mechanisms.

Particularly effective in seismic retrofit applications where ductility and energy dissipation are critical.

3. Structural Applications and Performance Enhancements

CFRP strengthening is employed across a broad spectrum of structural applications, including:

3.1 Flexural Strengthening of Beams and Slabs

CFRP laminates applied to the tension face increase moment capacity by up to 100% while maintaining serviceability limits.

Negative moment regions of continuous slabs can be reinforced with CFRP without intrusive demolition.

3.2 Shear Strengthening of Beams and Columns

U-jacketing or full wrapping with CFRP fabrics enhances shear capacity by 30–80%, preventing brittle shear failures.

Anchorage systems (e.g., CFRP spike anchors) mitigate premature debonding in high-shear zones.

3.3 Axial and Seismic Retrofit of Columns

Confinement Wrapping: Circular columns wrapped with CFRP exhibit increased axial load capacity (up to 200%) and ductility under seismic loading due to triaxial stress confinement.

Shear-Flexural Retrofit: Rectangular columns are strengthened with orthogonal CFRP layers to improve lateral load resistance.

3.4 Masonry and Historic Structure Rehabilitation

CFRP grids or fabrics reinforce masonry walls against out-of-plane bending and in-plane shear, preserving architectural integrity.

4. Design Considerations and Analytical Methodologies

The design of CFRP strengthening systems must adhere to international standards (ACI 440, fib Bulletin 90, ISO 14692) and incorporate the following critical aspects:

Failure Mode Analysis: Debonding, concrete crushing, and FRP rupture must be evaluated using fracture mechanics-based models.

Bond-Slip Relationships: The interfacial behavior between CFRP and concrete is modeled using cohesive zone formulations or empirical bond-slip laws.

Durability and Environmental Factors: UV degradation, freeze-thaw cycling, and alkaline exposure necessitate protective coatings (e.g., polyurethane topcoats).

Fire Resistance: Intumescent coatings or supplemental fireproofing may be required for structures exposed to elevated temperatures.

5.Sustainability and Lifecycle Benefits

CFRP strengthening significantly reduces the carbon footprint of structural retrofits by:

Minimizing Material Consumption: Thin CFRP layers replace bulky steel plates.

Extending Service Life: Eliminates corrosion-related maintenance costs.

Reducing Construction Waste: No demolition or concrete removal is required in most applications.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

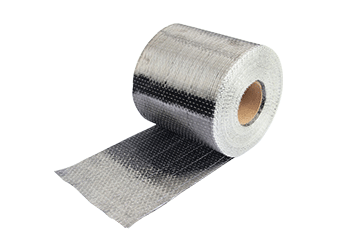

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Low viscosity, strong penetration carbon fiber primer for reinforced concrete surface to enhace the defect part

Good thixotropy carbon fiber leveling adhesive for concrete surface repairing