Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon Fiber

In the renovation of office buildings, factory upgrades, and historical building repairs, a material that is as light as a cicada's wing but as strong as steel is quietly changing the traditional reinforcement method. Carbon fiber reinforcement technology is like putting "invisible armor" on concrete floors, significantly improving the bearing capacity and durability without increasing the weight of the structure. This material revolution originated from aerospace technology and is quietly bringing about a technological revolution in the field of building reinforcement.

Why choose carbon fiber reinforcement?

Traditional reinforcement methods face three major pain points: increasing the cross-section of reinforced concrete causes a loss of 10-20cm in floor height, steel plate reinforcement brings anti-corrosion problems, and external prestressing construction is complicated. Carbon fiber materials show revolutionary advantages:

Ultra-high strength: T700-grade carbon cloth has a tensile strength of 3400MPa, which is 7 times that of ordinary steel bars

Extremely light and thin: 0.167mm thickness can replace 8mm steel plates, and almost no change in the appearance of the building

Corrosion resistance and durability: The service life in acid, alkali and salt environments exceeds 50 years. A shopping mall renovation case shows that the use of carbon fiber reinforcement increases the floor slab bearing capacity by 60%, while avoiding the loss of removing the ceiling due to traditional methods.

Core technology analysis

Carbon fiber reinforcement forms a complete technology chain:

Surface treatment:

Concrete grinding to expose aggregate (roughness ≥ 0.5mm)

Crack grouting (epoxy resin viscosity ≤ 500cps)

Angle treatment into R ≥ 20mm arc

Material construction:

Carbon fiber cloth pasting (lap length ≥ 150mm)

Multi-layer pasting interval ≤ 2 hours

Roller rolling to eliminate bubbles (compactness ≥ 95%)

Protection system:

Fireproof coating (fire resistance limit ≥ 1.5h)

UV protective layer (essential for outdoor use)

Anti-collision corner guard (installed in crowded areas)

Special scenario solutions

Customized solutions are required for different floor slab diseases:

Insufficient bearing capacity: carbon cloth is pasted longitudinally on the bottom of the slab (the fiber direction is consistent with the force)

Insufficient shear resistance: U-shaped hoop spacing ≤ 1/4 span (width ≥ 2/3 of the slab thickness)

Crack control: 100mm wide carbon cloth is pasted on both sides of the crack (stress release hole treatment)

Vibration sensitivity: Use viscoelastic damping glue (loss factor ≥ 0.3)

Breakthrough in material performance

Modern carbon fiber composite materials have achieved three major leaps:

Modified epoxy resin: low temperature curing type (construction possible at 5°C), high thixotropic type (no sagging on vertical surfaces)

Prefabricated board system: factory pre-cured carbon board (shortened construction period)

Smart carbon fiber: implanted optical fiber sensor (strain monitoring accuracy ±1με)

Process

Essential standard construction seven steps:

Bearing capacity identification (load test to 1.2 times the use load)

Finite element analysis (determine the fiber laying direction)

On-site layout (laser projection positioning error ≤ 2mm)

Base surface treatment (sandblasting to Sa2.5 level)

Adhesive application (serrated spatula thickness control 2-3mm)

Fiber material laying (ambient temperature ≥ 10℃)

Curing and curing (72 hours load protection)

The implementation of the dual-control quality system requires dual guarantees:

Process control:

Bond strength pull-out test (≥2.5MPa)

Hollowing rate detection (≤3% is qualified)

Fiber direction deviation ≤1°

Acceptance criteria:

Static load test deflection ≤L/400

Dynamic load test natural frequency change ≤5%

Infrared thermal imaging detection of bonding uniformity

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

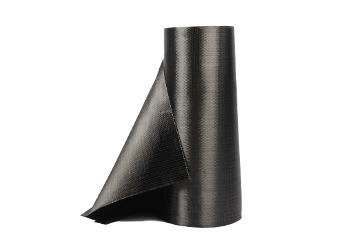

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.