Bea strengthening

CFRP reinforcement technology can be widely applied in China

According to the above characteristics and the actual production situation of the company, technical personnel after a comprehensive and comprehensive analysis, decided to adopt carbon fiber wrap reinforcement program to improve the bearing capacity.

This is a very good article to introduce to everyone. By Shenma Group nylon 66 salt technical transformation project preparation office

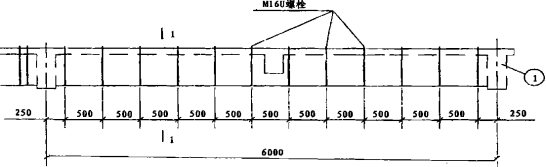

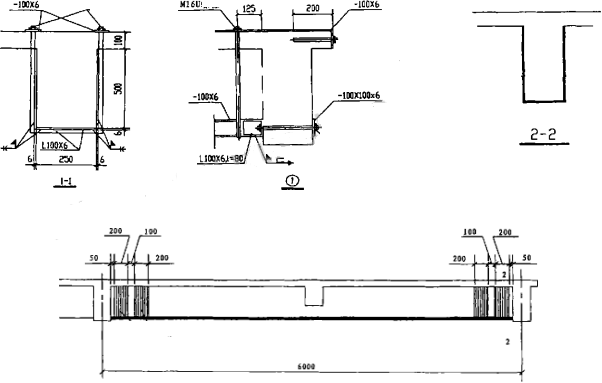

China Shenma Group Nylon 66 Salt Co., Ltd. is importing the world's advanced Nylon 66 salt production technology and equipment in the early 1990s. According to the company's development requirements of expanding reproduction and digging by-products, it is necessary to expand the production capacity of adipic acid plant, and adipic acid is produced by oxidation of cyclohexanol and nitric acid, so it is decided to increase. An oxidation reactor (B - R160 E) runs in series with the original 4 reactors. Due to the limitation of process conditions, an oxidation reactor must be added to the original oxidation reactor frame. After calculation, the force of the original oxidation reactor frame beam can not be satisfied, and must be strengthened.

1 Structural strengthening system

1.1 Before and after strengthening

According to the actual situation in the construction process, it is very difficult to construct the connection point between the beam and the frame column, and all the process pipelines around J GL-1 and J GL-2 need to be dismantled. The steel L100 *6 of the girder should be broken in many places, otherwise it is difficult to pass. In this way, the reinforcement effect of angle steel on the beam is reduced, the most disadvantageous is that the original reactor is required to stop before construction, which means that the continuous production process, the overall stop, is a loss to the enterprise.

1.2 Sticking carbon fiber wrap reinforcement method

In this scheme, CFRP reinforcement technology is a new type of structural reinforcement technology, which uses resin bonding materials to paste CFRP on the surface of concrete to achieve the purpose of strengthening the structure and components. The problems of dismantling the original process pipeline and stopping the installation around the reinforced beam in the reinforcement construction are solved fundamentally, thus ensuring the continuous operation and production of the production equipment.

According to the above characteristics and the actual production situation of the company, technical personnel after a comprehensive and comprehensive analysis, decided to adopt carbon fiber wrap reinforcement program.

2. Construction technology and requirements for sticking carbon fiber wrap

2.1 process principle

The strengthening mechanism is that carbon fiber sheet is bonded to the surface of concrete members with high-performance epoxy binder, and good tensile strength of carbon fiber sheet is used to enhance the bearing capacity and stiffness of the members.

2.2 process and operation requirements

Surface treatment, brushing, leveling, bonding, CFRP protection.

2. 2.1 surface treatment

(1) remove the deteriorated concrete such as spalling, loose and honeycomb corrosion on the surface of the reinforced component.

(2) The surface of the component requires the convex surface to be smoothed to expose sand, stone and cement (which is the key treatment to ensure the interaction between CFRP and concrete);

(3) Clean the concrete surface and keep it dry.

(4) use the repair material to smooth the surface repair.

2. 2.2 brush primer

(1) Make the base glue.

(2) The primer is evenly coated on the surface of concrete with a roller brush, and it is required to be immersed in the pores of concrete. After the adhesive solidifies, the next step is taken.

2. 2.3 leveling treatment

(1) compounding leveling materials;

(2) The surface of concrete surface is filled with leveling material, and there should be no edges and corners.

(3) Apply the leveling material at the corner to repair a smooth circular arc with a radius of not less than 20 mm;

(4) When the surface of the leveling material is touched or dried, the next step is to be constructed.

2. 2.4 paste carbon fiber cloth

(1) cutting carbon fiber cloth according to the size of the design requirements, the size deviation should not exceed 20 mm;

(2) Prepare impregnated resin adhesive and apply evenly to the part to be pasted.

(3) The special roller is used to roll along the fiber direction for many times to extrude bubbles and make the impregnated resin glue fully immersed in the carbon fiber cloth. If air is found, measures are taken to eliminate the air and the carbon fiber cloth is required to be straight after rolling.

(4) repeat the steps above and then paste on the next layer when the surface of the fabric is touched or dried.

(5) apply resin impregnated evenly on the surface of the final layer of CFRP.

2. 2.5 protection

The surface of the strengthened carbon fiber cloth should be protected by plaster or fire-retardant coating.

3 Concluding remarks

Carbon fiber reinforced plastics (CFRP) technology began in the 1980s in the United States, Japan and other developed countries, China started relatively late, there is no domestic standard specification, inspection and acceptance based on enterprise standards. Carbon fiber cloth is an imported product. Carbon fiber cloth used for reinforcing the beam of 66 salt oxidation reactor is Hertz composite material of U. S. A. The model is C300-C (0.167mm). The CFRP reinforcement has the advantages of simple construction, fast construction, fire protection, acid and alkali resistance, and less increase of dead weight after reinforcement. It is believed that CFRP reinforcement technology can be widely applied in China.