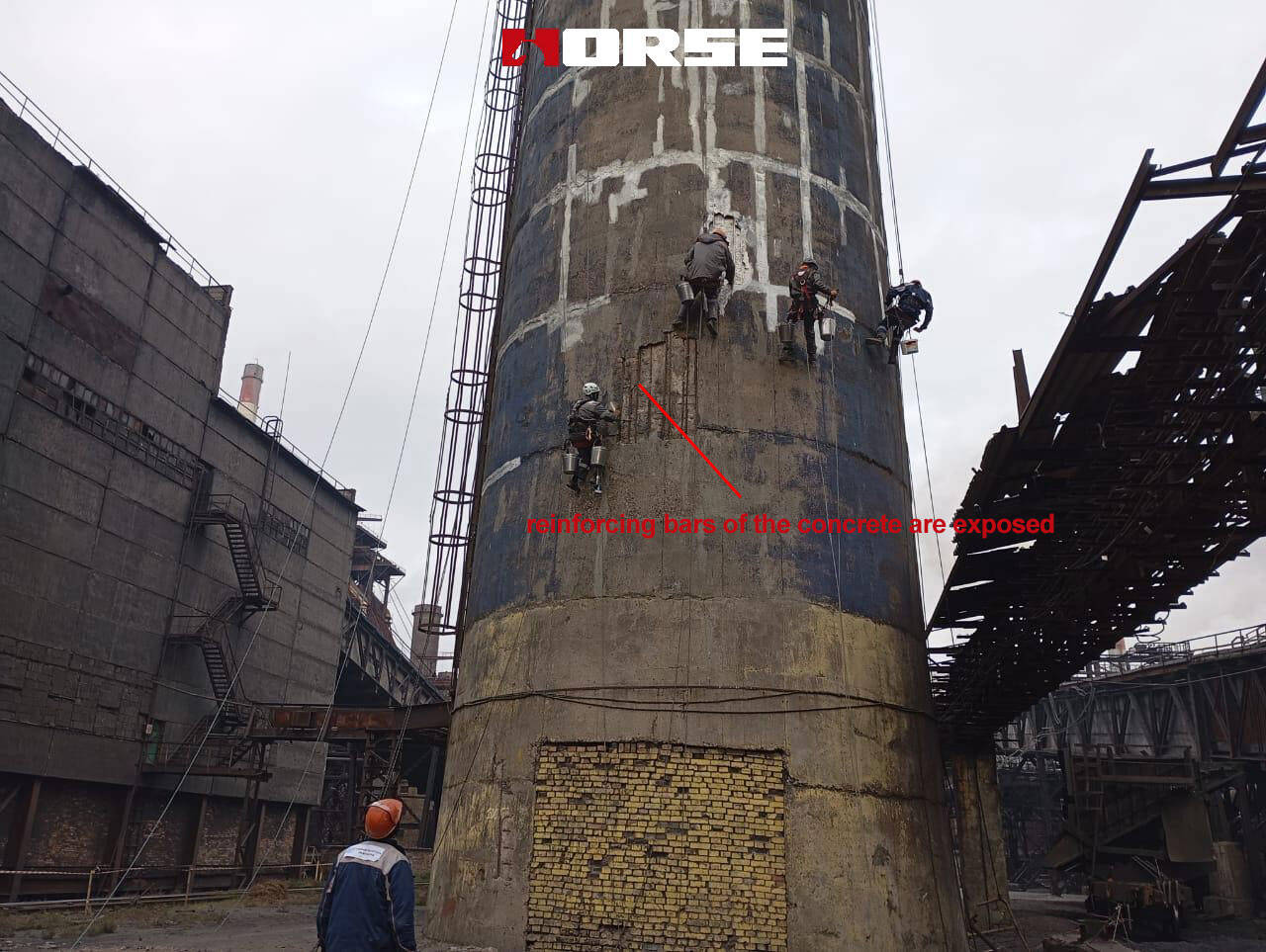

Reinforcement Chimneys with Cracks and Exposed Rebars

Carbon Fiber

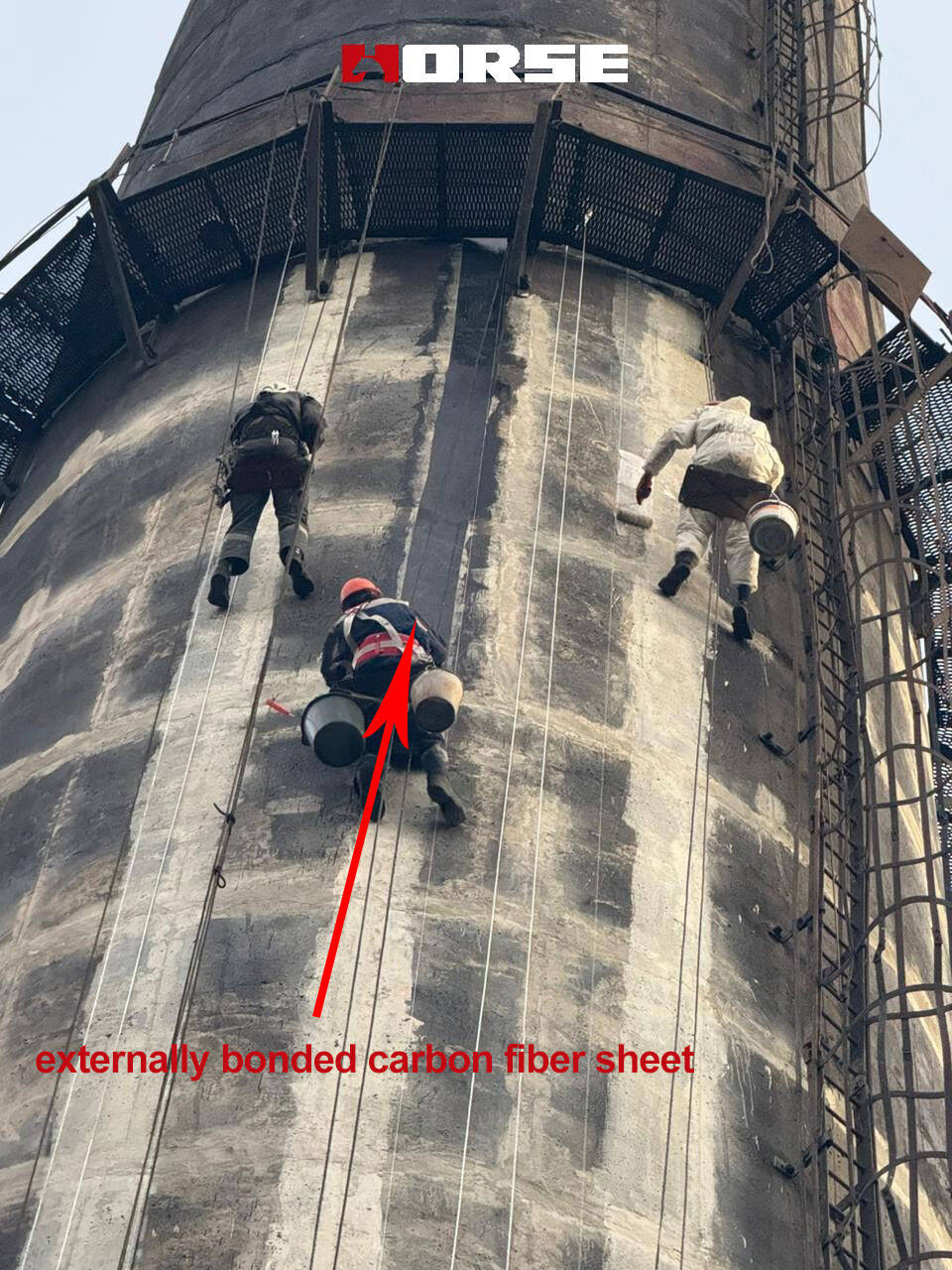

When attached to the surface of a chimney, the carbon fiber and the concrete structure form a whole. When the chimney is under load, the carbon fiber can bear the force together with the concrete and steel bars.

When the chimney is working normally, the concrete and steel bars jointly bear various loads on the chimney, including the chimney's own gravity, wind load, temperature stress, etc. When the steel bars are exposed, the bonding force between the steel bars and the concrete is destroyed, and the two cannot effectively cooperate to bear the force. For the cracked parts, the concrete in the area is no longer continuous and cannot completely transfer stress, resulting in a reduction in the overall bearing capacity of the chimney.

Exposed steel bars will quickly react chemically with oxygen and moisture in the air and rust. The volume of rust is much larger than the original iron, which will produce expansion force on the surrounding concrete, causing the concrete to further crack and peel, resulting in a reduction in the effective cross-sectional area of the steel bars, thereby reducing the bearing capacity of the steel bars and further weakening the structural strength of the chimney.

Carbon fiber materials have excellent mechanical properties, and their tensile strength is much higher than that of ordinary steel. When attached to the surface of a chimney, the carbon fiber and the concrete structure form a whole. When the chimney is under load, the carbon fiber can bear the force together with the concrete and steel bars. For chimneys with exposed steel bars and cracks, the carbon fiber can bear part of the tensile force originally borne by the damaged concrete and steel bars, thereby improving the bearing capacity of the chimney.

Carbon fiber cloth has a high elastic modulus and good flexibility. When pasted on the crack surface of the chimney, it can bridge the crack. It can connect the concrete on both sides of the crack, so that when the chimney is under load, the concrete on both sides of the crack can still work together to avoid stress concentration at the crack and further expansion of the crack.

For small cracks, the pasting of carbon fiber cloth can prevent the development of cracks. For existing larger cracks, carbon fiber cloth can limit the deformation of the cracks and keep the cracks stable, thereby repairing and reinforcing the crack structure of the chimney.

Chimney surface treatment

1) Cleaning surface impurities

First, use a high-pressure water gun to rinse the chimney surface to remove loose impurities such as dust and soot. For pollutants such as oil and grease that are difficult to wash off, use acetone or special cleaning agents to wipe and clean.

For biological dirt such as moss and mold on the surface of the chimney, appropriate biological cleaning agents or mechanical scraping methods can be used to clean it.

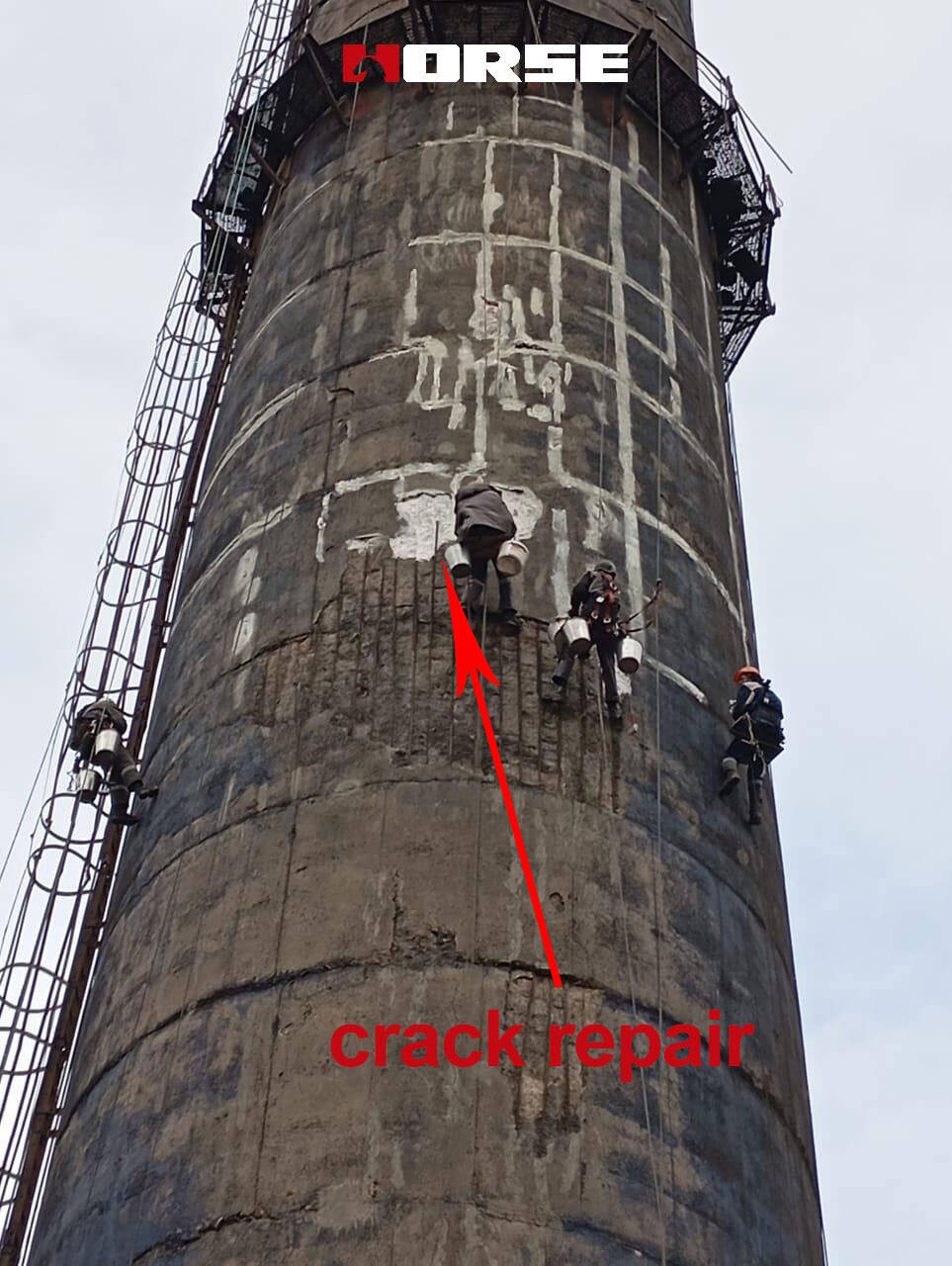

2) Crack treatment

Surface sealing: For fine cracks with a width of less than 0.2mm, epoxy resin glue is used for surface sealing to prevent water vapor intrusion. Use a brush to evenly apply the glue on the crack surface, and the coverage width should exceed the edge of the crack by 20-30mm.

Pressure injection: For cracks with a width greater than 0.2mm, pressure injection of epoxy resin is used for treatment. Drill holes at both ends of the crack, install injection nozzles, and seal the crack surface with sealant. Inject epoxy resin glue into the crack at a certain pressure through the injection equipment until the crack is completely filled. When glue flows out of the adjacent injection nozzle, stop injection and close the injection nozzle.

3) Steel bar treatment

For exposed steel bars, first use a wire brush and angle grinder to thoroughly remove the rust and oxide layer on the steel bar surface until the metallic luster is exposed.

Then apply two coats of anti-rust paint on the steel bar surface. Apply the second coat after the first coat is dry. The thickness of each coat should be even to avoid dripping or missing paint.

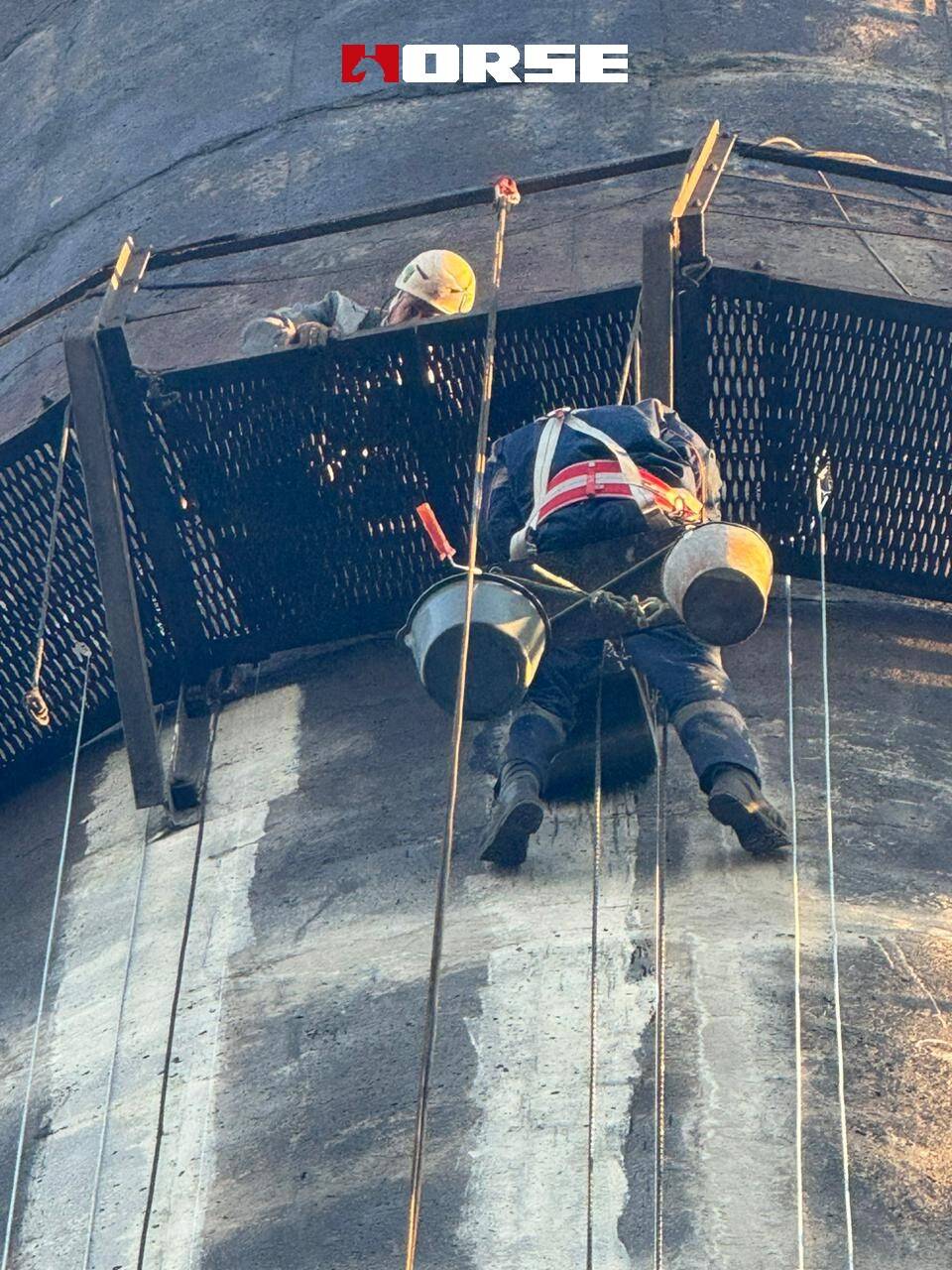

Carbon fiber bonding

1) Apply impregnation glue

On the surface of the chimney that has been coated with primer and cured, use a brush or scraper to apply impregnation glue. The coating thickness should be uniform, about 1-2mm, to ensure that there is enough glue in the entire pasting area.

The application range should be slightly larger than the pasting range of the carbon fiber cloth. During the application process, be careful to avoid bubbles in the glue.

2) Paste the carbon fiber cloth

Place the cut carbon fiber cloth quickly and accurately on the part where the impregnation glue is applied, and gradually spread it from one end to the other end. At the same time, use a scraper or a special degassing tool to scrape and press from the center of the carbon fiber cloth to the edge to squeeze out the air so that the carbon fiber cloth fits tightly to the surface of the chimney.

For the corners of the chimney, the carbon fiber cloth should be bent and pasted to ensure that it is firmly pasted without hollows. If the carbon fiber cloth is found to be wrinkled or not tightly pasted during the pasting process, it should be uncovered and pasted again in time.