Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

CFRP Strengthening

Structural member strengthening with bonded fiber composite materials is a technique used to enhance the load-bearing capacity and performance of existing structures. Bonded fiber composites, such as carbon fiber reinforced polymer (CFRP) or glass fiber reinforced polymer (GFRP), are lightweight and high-strength materials that can be applied to strengthen various structural elements, including beams, columns, slabs, and walls.

The process of strengthening structural members with bonded fiber composites typically involves the following steps:

Surface Preparation: The surface of the structural member to be strengthened is prepared by removing any loose or deteriorated material, cleaning, and roughening the surface. This step ensures proper adhesion between the composite material and the existing structure.

Bonding Adhesive Application: An appropriate bonding adhesive is applied to the prepared surface. The adhesive acts as a bonding agent between the existing structure and the fiber composite material.

Composite Material Installation: The fiber composite material, such as CFRP or GFRP sheets or strips, is positioned onto the bonding adhesive while it is still tacky. The composite material is carefully aligned with the structural member's axis and applied with sufficient pressure to ensure good contact and adhesion.

Curing and Bonding: The bonding adhesive is allowed to cure, forming a strong bond between the structural member and the composite material. This curing process may involve the application of heat, pressure, or a combination of both, depending on the specific adhesive and composite material being used.

Structural Integration: Once the bonding adhesive has fully cured, the strengthened structural member becomes an integral part of the composite system. It benefits from the increased strength and stiffness provided by the bonded fiber composite material.

The use of bonded fiber composite materials for structural member strengthening offers several advantages, including:

Increased Load-Carrying Capacity: The addition of fiber composites enhances the structural member's strength, enabling it to carry higher loads and resist deformation.

Lightweight Solution: Fiber composites are lightweight compared to traditional strengthening methods like steel plates or concrete jackets. This reduces additional dead load on the structure.

Durable and Corrosion-Resistant: Fiber composites are highly resistant to corrosion, making them suitable for both indoor and outdoor applications.

Minimal Disruption: The strengthening process is relatively non-intrusive, causing minimal disruption to the occupants or operations within the structure.

Design Flexibility: Fiber composites can be tailored to specific strengthening requirements, allowing for customized solutions based on the structural member's needs.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

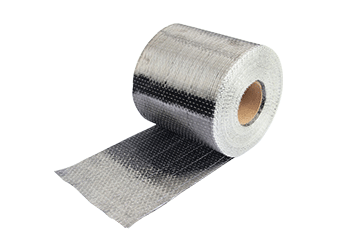

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

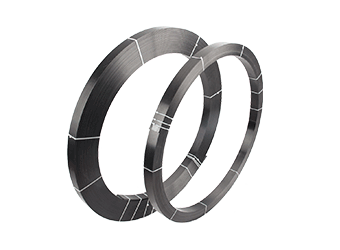

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair