• Technical data sheet:

• Technical data sheet:

• Short construction period

• Short construction period

• Raw material, 4900~5500Mpa aviation raw fiber

• Raw material, 4900~5500Mpa aviation raw fiber

• High strength, high modulus

• High strength, high modulus

• Load increases

• Load increases

• Beams strengthening

• Beams strengthening

• Concrete substrate

• Concrete substrate

• Civil buildings

• Civil buildings

HM-120CP carbon fiber plate adhesive, designed for HORSE carbon fiber strip/laminate.

HM-120CP carbon fiber plate adhesive, designed for HORSE carbon fiber strip/laminate.

• Setting out according to design

• Setting out according to design

Manufacturer of Carbon Fiber Strip

HM- 1.2T carbon fiber strip ↓

HM- 1.4T carbon fiber strip ↓

• Product catalog:

Horse FRP strengthening system ↓

• Design software:

Horse FRP Strengthening Design Software ↓ ↓

• Videos:

Tensile strength test

Factory

Manufacturer of Carbon Fiber Strip

HM- 1.2T carbon fiber strip ↓

HM- 1.4T carbon fiber strip ↓

• Product catalog:

Horse FRP strengthening system ↓

• Design software:

Horse FRP Strengthening Design Software ↓ ↓

• Videos:

Tensile strength test

Factory

Advantages of CFRP Strip Strengthening

• No maintenance required

• Easy installation, low installation cost

• Light weight, no influence to original structure

• Corrosion resistance, long-term effect of 50 years

• Cost effective compared with other retrofitting method

• 1 layers of CFRP laminate is equivalent to 4-8 layers of CFRP fabric

Advantages of CFRP Strip Strengthening

• No maintenance required

• Easy installation, low installation cost

• Light weight, no influence to original structure

• Corrosion resistance, long-term effect of 50 years

• Cost effective compared with other retrofitting method

• 1 layers of CFRP laminate is equivalent to 4-8 layers of CFRP fabric

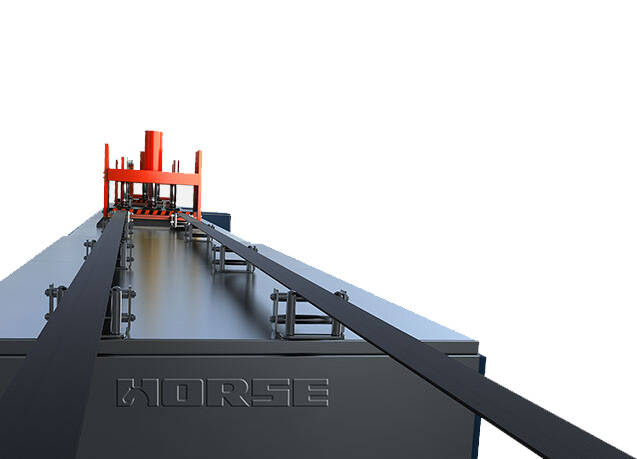

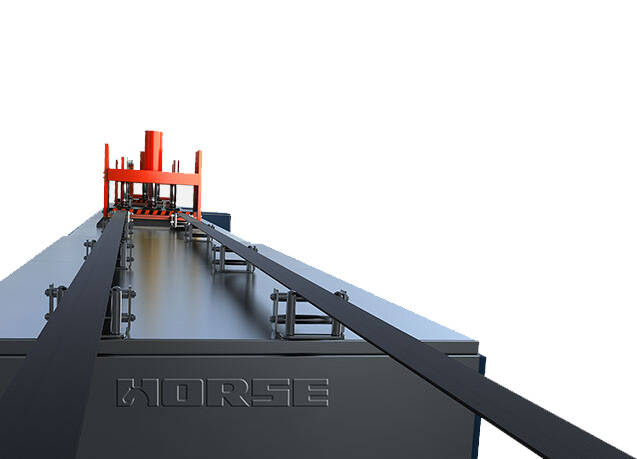

Manufacturer of Unidirectional Carbon Fiber Laminate

• Donier, 3 carbon fiber plate production lines, 2,000 meters per day

• Stock, 10,000 meters

• Factory, 5,000 square meters

• Laboratory, laboratory and 3 technologies

• Test and report, third party testing reports, ASTM-D3039

• Projects, 90000+ projects from 100 countries

Manufacturer of Unidirectional Carbon Fiber Laminate

• Donier, 3 carbon fiber plate production lines, 2,000 meters per day

• Stock, 10,000 meters

• Factory, 5,000 square meters

• Laboratory, laboratory and 3 technologies

• Test and report, third party testing reports, ASTM-D3039

• Projects, 90000+ projects from 100 countries

Key Characteristics of Carbon Fiber Strip

• Light weight

• Easy to install

• Easy to check after construction

• Environmental friendly

• Outstanding fatigue resistance, alkali resistance, acid resistance

Key Characteristics of Carbon Fiber Strip

• Light weight

• Easy to install

• Easy to check after construction

• Environmental friendly

• Outstanding fatigue resistance, alkali resistance, acid resistance

Application Range of Carbon Fiber Strip Strengthening

• Seismic reinforcement

• Improve structural state

• Damage of structural parts

• Change the structural function

• Remit mistakes in design and construction

Application Range of Carbon Fiber Strip Strengthening

• Seismic reinforcement

• Improve structural state

• Damage of structural parts

• Change the structural function

• Remit mistakes in design and construction

Structural Elements of Carbon Fiber Laminate Strengthening

• Slabs strengthening

• Walls strengthening

• Pipes strengthening

• Pier caps strengthening

Structural Elements of Carbon Fiber Laminate Strengthening

• Slabs strengthening

• Walls strengthening

• Pipes strengthening

• Pier caps strengthening

Base Substrates of Carbon Fiber Laminate Strengthening

• Steel substrate

• Masonry substrate

• Timber substrate

Base Substrates of Carbon Fiber Laminate Strengthening

• Steel substrate

• Masonry substrate

• Timber substrate

Construction Field of Carbon Fiber Laminate Strengthening

• Bridges

• Tunnels

• Piers/wharfs

• Airports

• Highways, railways

Construction Field of Carbon Fiber Laminate Strengthening

• Bridges

• Tunnels

• Piers/wharfs

• Airports

• Highways, railways

Manufacturer Epoxy System

Manufacturer Epoxy System

How to Use Horse Carbon Fiber Strip

• Polish the surface of concrete surface

• Prepare ingredients

• Applying HM-120CP adhesive

• Installation Horse carbon fiber reinforced strip plate

• Maintenance

How to Use Horse Carbon Fiber Strip

• Polish the surface of concrete surface

• Prepare ingredients

• Applying HM-120CP adhesive

• Installation Horse carbon fiber reinforced strip plate

• Maintenance

Horse CFRP Plate's Date Sheet

![]() HM-1.2T Technical Data Sheet.pdf

HM-1.2T Technical Data Sheet.pdf

![]() HM-1.4T Carbon Fiber Laminate Technical Data Sheet.pdf

HM-1.4T Carbon Fiber Laminate Technical Data Sheet.pdf

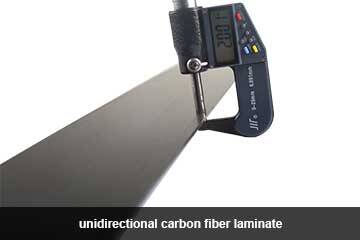

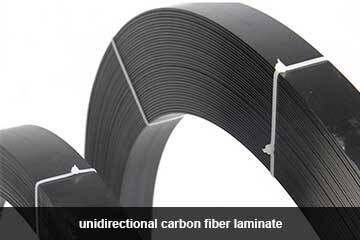

| Item | HM-1.2T Carbon Fiber Laminate | HM-1.4T Carbon Fiber Laminate | HM-2.0T Carbon Fiber Laminate | HM-3.0T Carbon Fiber Laminate |

| Thickness(mm) | 1.2 | 1.4 | 2.0 | 3.0 |

| Length(m) | 100 | 100 | 100 | 100 |

| Width(mm) | 50、100 | 50、100 | 50、100 | 50、100 |

Density(g/cm3) | 1.6 | |||

| Base | Carbon fiber reinforced polymer with an epoxy resin matrix | |

| Shelf Life | Unlimited (no exposure to direct sunlight) | |

| Color | Black carbon fiber laminate | |

| Tensile Strength | Mean Value | 3100MPa |

| Design Value | 2600MPa | |

| Modulus Of Elasticity | Mean Value | 165,000MPa |

| Design Value | 160,000MPa | |

Elongation at Break | 1.7% | |

| Thickness | 1.2mm, 1.4mm, 2.0mm, 3.0mm | |

| Temperature Resistance | >300° F(>150℃) | |

| Fiber Volumetric Content | >68% | |

| Density | 0.058 lbs./in 3 (1.6g/cm3) | |

Package

The length of Horse carbon fiber laminate is 100m, the width is divided into 50mm, 100mm; the thickness is divided into 1.2mm, 1.4mm, 2.0mm, 3.0mm. Roll into a ring and use a belt to bind. Other specifications can be customized.

Operation Process of Horse CFRP Strip/Laminate/Plate Strengthening

Carbon Fiber Plate Strengthening Video(click it)

Setting line according to design;

Polish the surface of concrete surface to remove painting of

surface, blow out that floating dust with compressed air;

Prepare ingredients: agitate component A and B evenly in

packaging bucket by weighting in accordance with the weight

ratio A:B=2:1;

Applying adhesive: paste the above mixed glue compounds onto

the surface of carbon fiber strip evenly, please avoid bubbles;

Installation: paste the carbon fiber plate onto the concrete surface

and fixed with steel strip;

Remove excessive glue compounds around, and fix with steel

framework;

Maintenance: conservation time should be no less than 24 hours

at room temperature.