Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

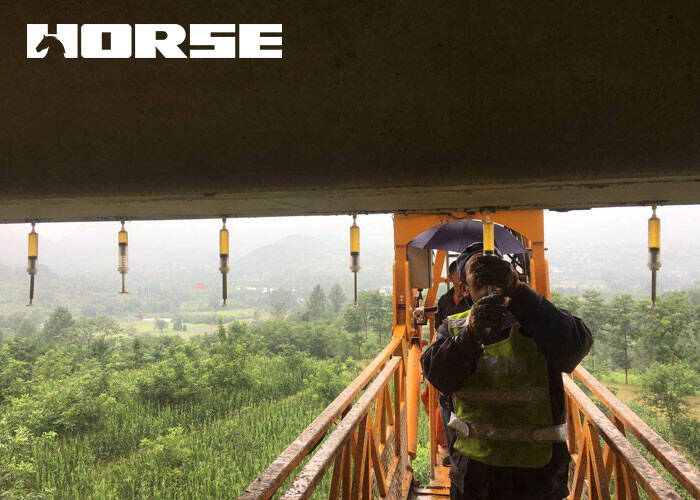

Bridge Inspection and Bridge Structure Testing Methods

Bridge inspection is a must-do work before bridge maintenance, repair and reinforcement. It is a reliable guarantee for determining whether the maintenance and reinforcement plan is feasible and correct. It is also an indispensable and important part of bridge assessment, maintenance, repair and reinforcement.

According to the scope, depth, method and purpose of the inspection, bridge inspection is mainly divided into two categories: regular bridge inspection and bridge structure inspection.

Frequent bridge inspections

Frequent bridge inspections include daily bridge inspections and periodic bridge inspections, which are mainly conducted by bridge management departments. Daily bridge inspections are generally conducted once a month; periodic bridge inspections are conducted approximately once every 3 to 5 years.

Although regular bridge inspections also use simple tools or instruments for testing, they are mainly based on visual inspections of the bridge's appearance, and the evaluation of inspection results is mostly based on surface phenomena and experience.

Special inspection of bridges (bridge structure inspection)

Special inspection of bridges is to further accurately determine the technical condition of bridges on the basis of regular inspection of bridges.

Usually, special inspection of bridges is required in the following four situations:

1) When regular inspection of bridges cannot determine the cause of bridge diseases and bearing capacity;

2) Before major bridge repair and reinforcement projects;

3) After major natural disasters, accidents, overweight vehicles passing over bridges and other special events;

4) When it is necessary to assess the actual working condition of bridge structures.

Special inspection of bridges (bridge structure inspection) generally consists of three parts: bridge appearance damage inspection, bridge structure and material inspection, and bridge load test.

Bridge field inspection projects

Bridge field inspection includes bridge appearance defect inspection, bridge structure material inspection and bridge load test.

01 Bridge appearance defect inspection

We have a preliminary and basic understanding of the appearance damage of the bridge structure, and score and classify the damage according to the bridge, which provides a basis for the next step of bridge structure material inspection.

02 Bridge structure material testing

On the basis of the above, further bridge structure material testing is carried out on bridges with serious appearance damage to deeply understand the working status and potential adverse effects of bridge structure materials, and predict development trends to provide a technical basis for judging the durability and reliability of bridges. The key points of bridge structure material testing are as follows:

1) Concrete strength testing

It is mainly carried out by rebound method or ultrasonic-rebound method.

The concrete surface rebound value is detected by a rebound hammer, and the sound velocity in the concrete is detected by an ultrasonic instrument. The concrete strength is calculated based on the correlation between the concrete strength (R) and the rebound value and the propagation speed of ultrasonic waves in concrete (V). When using the rebound method, the influence of carbonization depth should be considered. Concrete strength is an important indicator for bridge structure assessment.

2) Rebar corrosion detection

The detection content includes steel bar corrosion potential, concrete chloride ion content, concrete resistivity and concrete carbonization depth.

Steel bar corrosion detection is to comprehensively evaluate the steel bar corrosion status in bridge structures by testing the environment of the steel bars (such as chloride ion content in concrete, concrete resistivity and carbonization depth, etc.) and the natural potential of the steel bars themselves.

3) Steel bar distribution and concrete cover thickness detection

The detection of structural materials is to use various special instruments and equipment to conduct on-site sampling and record the detection data of the steel bars and concrete materials of the bridge structure, and then evaluate them according to the bridge structure material detection and evaluation standards and the working status of the bridge structure materials, and at the same time conduct a preliminary analysis of the causes.

03 Bridge load test (dynamic and static load test)

After the appearance defect inspection and structural material inspection of the bridge, bridge load test is carried out on bridges with serious damage and poor structural material condition according to the inspection results.

Dynamic load test can determine the dynamic characteristic parameters of bridge structure and the forced vibration response under dynamic load, and determine the dynamic effect and use conditions of bridge under vehicle load.

Static load test designs different loading conditions according to the equivalent principle according to different bridge types and different design loads. By actually loading the bridge, the deformation and stress state of the most unfavorable section of the bridge are detected, so as to infer the actual working state and use bearing capacity of the bridge structure under load.

The method of bridge load test is to install various sensors on the main control section of the bridge structure, and record the stress and deformation data of the bridge through instruments under the specified load.

Conclusion and basis of bridge inspection data analysis

The conclusion of bridge inspection data analysis includes three aspects:

01 Evaluation conclusion of bridge structure material status

Based on the test results of bridge structure materials, the current status of bridge structure materials is analyzed and a clear assessment is given. The focus is on concrete strength, steel corrosion and bridge appearance damage.

02 Evaluation conclusion of bridge bearing capacity

Through the inspection and calculation of bridges, the current bearing capacity of bridges is evaluated, and clear conclusions are given and classified.

03 Prediction and suggestions on bridge working status

Through the analysis of the current bridge inspection results, the future working status of the bridge is predicted, the possible development trend is pointed out, and suggestions are provided for future bridge maintenance.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

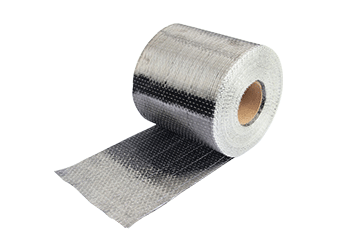

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

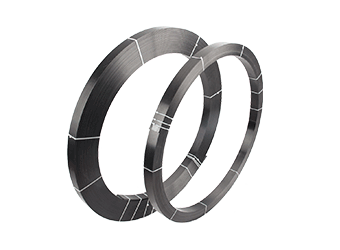

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.