Beam strengthening

Carbon fiber fabric(FRP fabric) strengthening

Carbon fiber is a new kind of high strength struatural strengthening material. It has been used for more than ten years in China and has been widely used abroad. Although FRP reinforcement technology is a new product, it has gradually become a part of civil engineering.

Carbon fiber is a new kind of high strength struatural strengthening material. It has been used for more than ten years in China and has been widely used abroad. Although FRP reinforcement technology is a new product, it has gradually become a part of civil engineering.

1 advantages of carbon fiber(FRP) reinforcement

1) high strength and good effect.

The tensile strength of CFRP is over 3 550 MPa, the tensile modulus of elasticity is over 2.35 *105 MPa, which is similar to the elastic modulus of steel bar. It has good flexibility and is easy to cut. It is suitable for the reinforcement and repair of concrete structures.

2) strong corrosion resistance and good durability.

Carbon fiber materials have stable chemical properties, are not easy to react with acid, alkali and other chemical reactions, and have good corrosion resistance and durability.

3) light weight and small thickness.

The specific gravity of carbon fiber is only 1/4 of that of steel, and the thickness is less than 0.5 mm. Therefore, it can play a strong reinforcing effect without increasing the dead weight and section size of the original structure.

4) wide range of uses.

Structural reinforcement and aseismatic reinforcement applied to various components of industrial and civil buildings.

It can also be used for reinforcement of complex forms such as surfaces and joints.

5) the construction process is simple and easy to operate.

In the reinforcement project, no large-scale construction mechanism and turnover materials, no large construction site, no wet operation, high efficiency, good economy.

6) strong function.

A. provides greater lateral displacement capacity and toughness and strength when seismic strengthening.

B. increases (bridge) beam, plate, column compression, shear and bending capacity, for overload reinforcement.

C. protects concrete and steel from external environment (moist, corrosive medium) erosion.

2 project overview

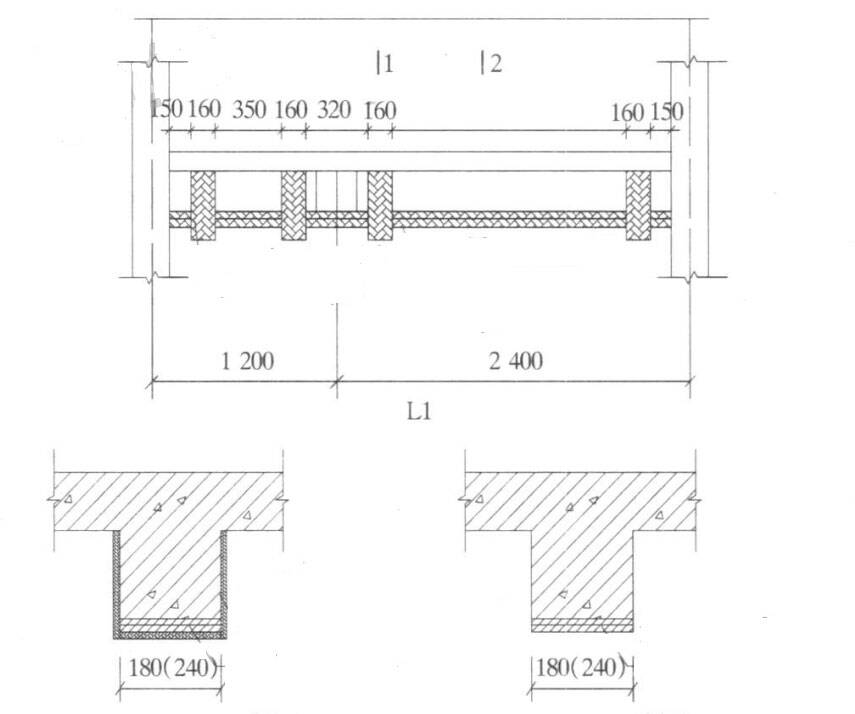

A four-star hotel in a city was built in the 1950s and was designed by Soviet experts. It is a brick-concrete structure with seven stories. It was not designed for seismic fortification. In April 2002, the structure was seismic strengthened, and the internal layout of the hotel building was adjusted. Some load-bearing walls need to be removed, and the corresponding ring beams need to be strengthened. The thickness of the staircase is more than 60 mm, and the reinforcement has a single layer and a spacing of 300 mm. At the same time, the construction of the project is early, has reached the service life, after the scheme demonstration and economic and technical feasibility comparison, decided to use carbon fiber(FRP) composite wrap beam reinforcement.

200g carbon fiber fabric, 0.111mm thickness

3. process flow

Unloading, bottom treatment, coating the bottom resin, leveling the construction surface, sticking carbon fiber sheet, surface protection and decoration. In view of the actual situation of the project, unloading should be carried out in the reinforcement, and the roof and beam of the structure should be supported. From the first floor (no basement) to reinforce, the upper floor surface of all the debris clean, the decorative surface of the beam side all clear, polished clean, clean up to the structural base, the first floor reinforcement after the completion of the next floor construction

4. construction effect

The project was completed in October 2002. The time limit for the part strengthened with carbon fiber is 25 days. After completion, the hotel has received guests and operated normally for more than 5 years. There is no quality problem. And the construction effect of the process is good, easy to operate, shorter construction period, has been the design unit, supervision unit, the owner's praise.