Structural beams strengthening

Carbon plate and carbon wrap strengthening

We selected strengthening by carbon fiber plate and carbon fiber wrap with reference to location of additional loads and existing layout of RC Beams.

A. Existing Structure Description:

As the Structural Engineers for The Victoria Commercial Bank building at Two Rivers, Ruaka, Nairobi, we have designed the building with 800x400mm beams and 175mm thick RC solid slabs. Total of Dead load and Imposed loads is 17KN/m2 taking into account light weight infill partition walls. Victoria Commercial Bank is in process of fitting out for new branch on 7th Floor. Heavy equipment such as Lockers, Strong Room door and Mantrap and CIT unit will be placed on the floor slab. The Strong Room and Locker Rooms is built with 200mm thick stone walls and secured with heavy 4mm thick MS steel plates all around. These additional weights are not considered during initial design, therefore; external strengthening of the structure at specific locations has been implemented. We selected strengthening by carbon plate with reference to location of additional loads and existing layout of RC Beams.

B. Photographs with Description

The following photographs with brief descriptions explain the stages of the Carbon Fiber Plate and Carbon Wrap Process:

Photo 1: Site preparation including covering all the walls & exposed surfaces with PVC sheets to protect against damage

Photo 2: Props were put up before carbon plating works were started as internal partition works were started.

Photo 3: Surface Preparation which involved removal of paint & the skimming coat on the RC beams by Sanding and Grinding.

Photo 4: Application of epoxy resin & fixing of Carbon Laminates (Plates) on the RC Beam soffits for tensile strengthening.

Photo 5: Supporting the applied Carbon Laminates with formwork for proper bonding.

Photo 6: Application of epoxy resin in preparation for installation of Carbon Fiber Wraps around the soffits of the down-stand RC beams for Shear strengthening

Photo 7: Marking around on the soffits of the RC Beams for installation of Carbon Fiber Wraps.

Photo 8: Fixed Carbon Laminates (Plates) on 7th Floor slab on Top of the RC Beam for resisting Negative Bending Moment Deflection which can cause hogging.

Photo 9: Fixed Carbon Laminates (Plates) on 7th Floor slab on Top of the RC Beam for resisting Negative Bending Moment Deflection which can cause hogging. Note, partition walls had to be cut to for continuous passing of Carbon Laminates.

Photo 10: On going Carbon Plating and Carbon Wrapping works. Note supporting props and form work to allow curing of epoxy glue. Propping was done intermittently as per progress of works.

Photo 11: Main Curved Primary Bean completely covered with Carbon Fiber Warp for enhanced strength

Photo 12: Photo away from Glass Wall: Completed Carbon Plating and Carbon Wrapping Works which involved installation of Fiber Laminates and Carbon Fiber Wraps bonded onto the RC Beams using Epoxy Resin as the adhesive and acting as external reinforcements to aid in accommodating extra loading on the 7th floor.

Photo 13: Photo towards Glass Wall: Completed Carbon Plating and Carbon Wrapping Works which involved installation of Fiber Laminates and Carbon Fiber Wraps bonded onto the RC Beams using Epoxy Resin as the adhesive and acting as external reinforcements to aid in accommodating extra loading on the 7th floor.

Conclusion:

External strengthening of the structure at specific locations has been implemented.

We recommended structural strengthening of the existing beams by Carbon Plating and Carbon Wrapping and selected ULTRATECH Building Solution Limited to execute the Carbon Plating and Carbon Wrapping Works. Carbon Plating and Carbon Wrapping is the use of carbon fiber laminates and carbon fiber wraps, bonding onto the beam using epoxy resin as the adhesive and acts as external reinforcement.

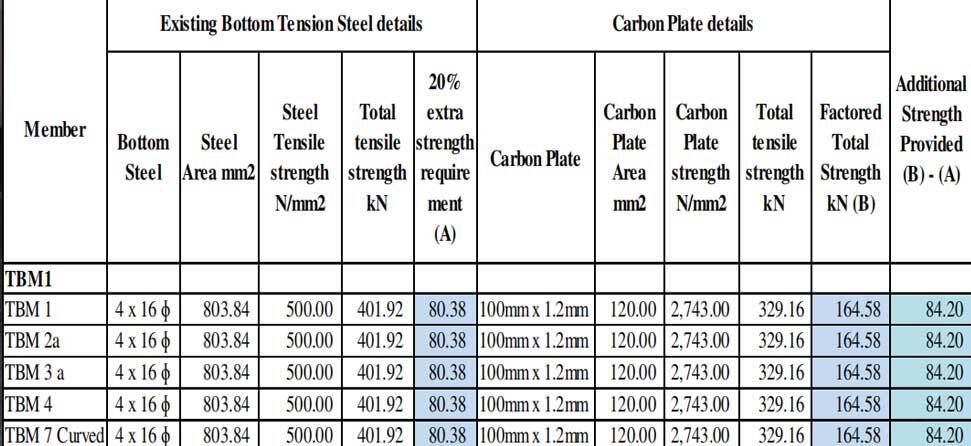

Where the heavy equipment will be located, the extra dead load is 6KN/m2 . The following 5Nos. of beams have been strengthened to take the extra loading.

Tbm 1 800x250mm Tbm 2a 800x400mm Tbm 3a 800x400mm Tbm 4 800x400mm Tbm 7 800x400mm

The External Strengthening of the Structure at selected locations has been done successfully as per requirement.

Following is the Table provides the data to support Carbon Plate Design Works.

Attachments:

Attached are the following Structural Drawings and Product Data Sheets:

A. Structural Drawing For 7th Floor Carbon Plating Works:

1. Drawing No.: BA/VCB/TR/0120/L12 Rev K: 7th Floor Layout Showing Beams for Carbon Plating.

2. Drawing No.: BA/VCB/TR/0120/CP: 7th Floor Beams For Carbon Plating

B. Data Sheets for Carbon Plates and Carbon Fiber used:

1. HM-1.2T Carbon Fiber Plate

2. HM-30 Carbon Fiber Fabric

3. Carbon Fiber Fabric - Horse Construction