Unidirectional carbon fiber cloth for beam strengthening

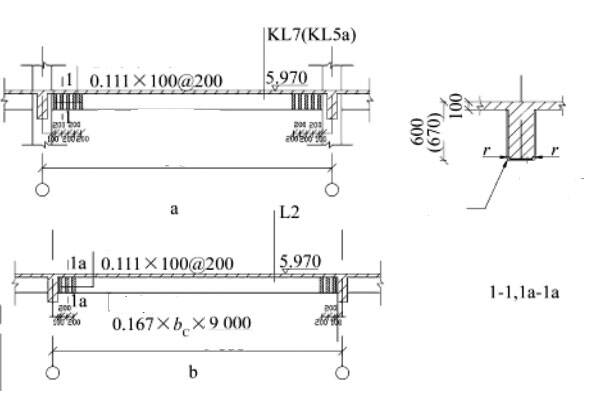

Unidirectional carbon fiber cloth fcfk is more than 3 000N /mm2; Ecf is equal to 2.1 x 105 N /mm2; thickness specification: 0.111mm, 0. 167mm.

After analysis, the unidirectional carbon fiber cloth was adopted. After the treatment, the structural performance is tested. After the requirements are met, the steel wire mesh is used to coat the mortar and smooth.

Project

Factory building project, frame 4 stories, bottom column concrete is poured first, then 2 stories floor beam and slab concrete are poured after 5 days. In the evening, pouring begins. Some secondary beams are found to deflect during pouring process. Emergency reinforcement is carried out to stop the expansion of the accident.

The reason for this accident is that the construction unit has not followed the procedure acceptance procedure, and the rigidity is insufficient to pass. The steel pipe fender supporting the secondary beam is directly placed on the foundation backfill, and the supporting bent is not supported by scissors. Two days before pouring concrete, it rained, part of the backfill subsided, the woodworking reinforcement was not in place, the construction unit did not carry out self-inspection, and no hidden accident was found. No supervisor or owner was notified before pouring.

After analysis, the unidirectional carbon fiber cloth was adopted. After the treatment, the structural performance is tested. After the requirements are met, the steel wire mesh is used to coat the mortar and smooth.

Structural strengthening materials

Unidirectional carbon fiber cloth fcfk is more than 3 000N /mm2; Ecf is equal to 2.1 x 105 N /mm2; thickness specification: 0.111mm, 0. 167mm.

Carbon fiber adhesive: primer, levleing adhesive, pregrant adhesive

Construction requirements

1.concrete base treatment

(1) the concrete base must remove the attachments, remove the oil dirt, and cut the flat formwork to rub the mouth.

(2) The surface is covered with wool to expose the new surface of concrete.

(3) In case of small defects (honeycomb, etc.), use structural adhesive to make up.

2. the construction sequence of sticking carbon fiber cloth: brushing the bottom glue, painting adhesive paste, sticking carbon fiber cloth and painting the cover glue.

Points for attention

(1) stick the carbon fiber cloth on the bottom of the beam, and finally attach the carbon fiber hoop.

(2) when laminating carbon fibre cloth, the second layer of construction can be carried out only after the first layer of laminating adhesive surface is dried, and so on.

Summary

The structural performance test report is qualified, the bottom of the beam is painted with cement mortar and steel wire mesh to be straight, and no cracks are observed in the later period, which achieves satisfactory reinforcement effect. The effect of CFRP strengthening beam and slab is very good.