Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

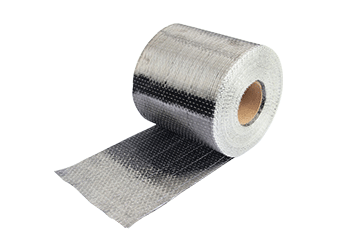

FRP composite materials mainly include glass fiber composite materials, carbon fiber composite materials and aramid fiber composite materials. Carbon fiber sheet have been widely used because of their high strength, high modulus, low density, and good corrosion resistance.

With the development of FRP reinforcement technology, the application of pipeline reinforcement and repair is becoming more and more widespread.

Reinforcement of fiber composite materials is to use the high strength of fiber materials and combine the adhesive resin to coat a composite material repair pipeline layer on the service of corroded or damaged pipelines to restore the service strength of pipelines with defects. The strength repair of the damaged pipe body without affecting the production has the advantages of no welding, no fire, non-stop, online, fast repair, safe operation, fewer construction personnel, no need for large equipment, low cost, etc., suitable for Various defects are the mainstream direction of pipeline reinforcement and repair. Not only that, the reinforcement of the composite material type can also be used to enhance the pressure of non-defective pipelines. Because this type of reinforcement does not need to be welded on the service pipeline, the risk of welding penetration and hydrogen embrittlement and cold embrittlement is avoided.

FRP composite materials mainly include glass fiber composite materials, carbon fiber composite materials and aramid fiber composite materials. Carbon fiber sheet have been widely used because of their high strength, high modulus, low density, and good corrosion resistance.

Carbon fiber sheet reinforcement advantages

The advantages of carbon fiber sheet for pipeline reinforcement and repair are as follows:

1. No welding and no fire, can be repaired under pressure operation;

2. Simple and fast construction and short operation time;

3. The modulus of elasticity of carbon fiber is very close to the modulus of elasticity of steel, which is beneficial for the composite material to carry as much pipeline pressure as possible, reduce the stress level of the pipeline with defects, and limit the expansion and deformation of the pipeline;

4. The carbon fiber has high tensile strength, which is extremely safe for pipeline repair; and the carbon fiber composite material has excellent creep resistance, and its strength remains basically unchanged as the service time increases;

5. The thickness of the carbon fiber sheet reinforcement layer is small, which is convenient for subsequent anticorrosive treatment;

6. Carbon fiber reinforced wrapping and laying methods are flexible. It can repair defects in girth and spiral welds (including high weld residual height and severely misaligned edges); it can also repair irregular pipe fittings such as elbows, tees, heads, etc .;

7. It can be used to repair and strengthen defects such as corrosion, mechanical damage and cracks. It can also be used to enhance the pressure of the entire pipe section, and has a wide range of applications.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

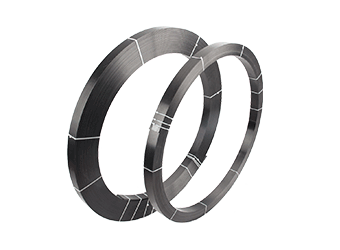

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.