Bridge with Rebars Corroded in Bangladesh

Carbon Fiber

Select language

Carbon Fiber

The bridges in Bangladesh have been in a humid environment for a long time and have been improperly maintained during use, which has caused the internal steel bars of the bridge to gradually corrode.

The bridges in Bangladesh have been in a humid environment for a long time and have been improperly maintained during use, which has caused the internal steel bars of the bridge to gradually corrode. The steel bar corrosion has seriously damaged the structural integrity of the bridge, greatly weakened the bearing capacity of the bridge, and brought major hidden dangers to the safe use of the bridge.

Challenge:

The humid climate accelerates the corrosion process of the steel bars, which seriously affects the durability of the bridge structure. Improper maintenance failed to detect and deal with the steel bar corrosion problem in time, causing the problem to continue to worsen. After the steel bars corrode, the bearing capacity of the bridge decreases, and it may not be able to meet normal traffic needs, and even pose a safety risk.

Solution:

In response to the above problems, the following reinforcement measures are taken:

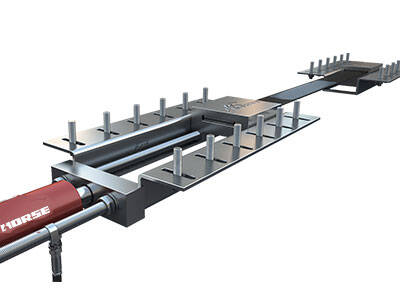

First, 3 pieces of HM-1.4*100mm carbon plates are pasted side by side at the bottom of the bridge beam. Carbon plates have the characteristics of high strength and high elastic modulus, which can effectively improve the bending bearing capacity of the bridge. In the process of pasting the carbon plate, it is necessary to ensure that the carbon plate fits tightly with the bottom of the bridge beam, and use professional construction technology and adhesives to ensure the pasting quality.

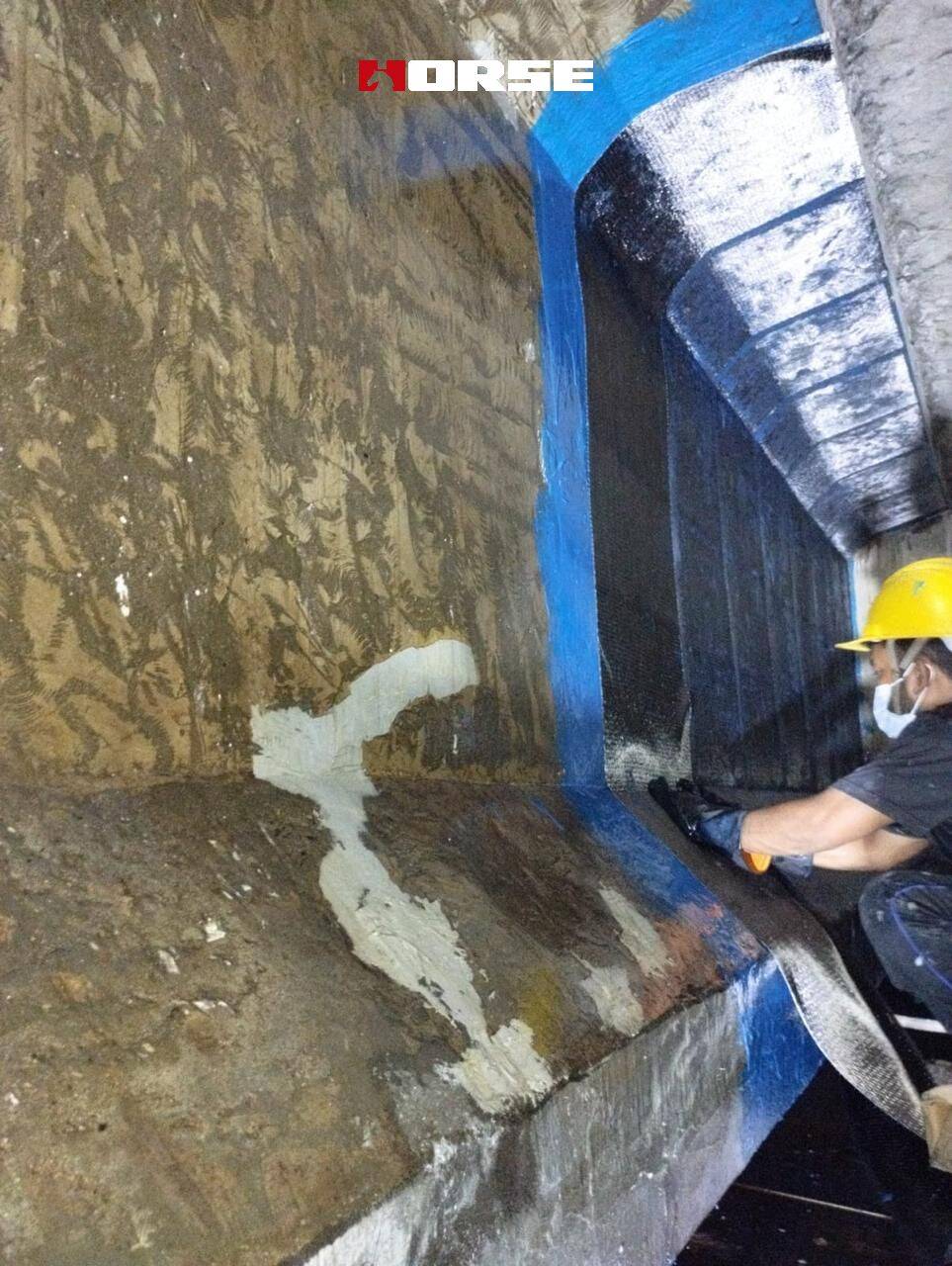

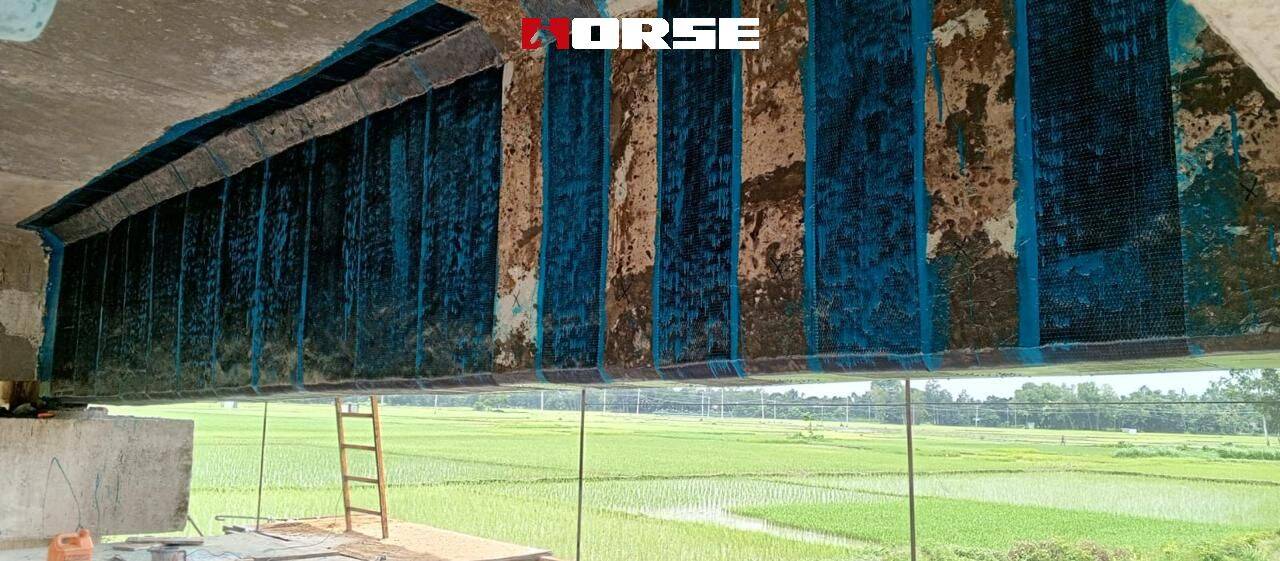

Then, use a special adhesive to stick HM-23 carbon fiber to the tensile part of the bridge to form a U-shaped hoop to wrap the bridge. Carbon fiber has the advantages of light weight, high strength, and corrosion resistance. It can enhance the shear bearing capacity of the bridge, while protecting the steel bars and delaying further corrosion of the steel bars.

Significantly improve the bearing capacity of the bridge so that it can meet normal traffic needs. Delay the corrosion process of the steel bars and extend the service life of the bridge. Enhance the structural stability and safety of the bridge and reduce safety hazards.

Website Map | Corporate | Contact | Privacy