Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Strengthening Openings in Concrete Floor Slabs

In actual production and daily life, floor openings are often involved due to functional modifications and the addition of equipment. On the one hand, after the opening of the floor slab, the original force transmission path and reinforcement are partially cut off, which will reduce the overall stiffness of the floor slab, reduce the structural integrity, and subsequently reduce the seismic performance of the building. On the other hand, opening holes in the floor slab can also weaken the bearing capacity around the opening slab, leading to concrete cracking and even damage.

Therefore, we should conduct internal force analysis and bearing capacity verification on the floor slab after opening, and adopt appropriate reinforcement methods based on differences in the properties, size, shape, and direction of the floor slab. Common reinforcement methods include compensating reinforcement and adding support beams.

Compensation reinforcement method

The increase in internal force and decrease in bearing capacity after opening the floor slab are directly related to the size of the opening, and can be simplified:

1) When b ≤ 300mm (the width of the opening perpendicular to the direction of the plate's stress) or the diameter of the opening D ≤ 300mm, and the number of cut steel bars is ≤ 5%, it can be left untreated.

2) When b ≤ 1000mm or the diameter of the hole D ≤ 1000mm, the number of cut steel bars is ≤ 20%, and the impact on the stress of the plate after opening is small. When reinforcement is only based on the structure, the compensation reinforcement method can be used to add the cut steel bars (Asfy) in the plate to the edge of the hole. For the convenience of construction, steel or fiber cloth is generally used as post reinforcement, and the total compensation amount should be ≥ 1.2 (Asfy).

When pasting steel plates or fiber cloth on the plate surface that bears negative bending moments, it is often hindered by the wall and cannot be arranged in a continuous manner. In this case, screws and short angle steel can be used to pass through the wall and anchor to transfer tensile force, and holes can be made in the corner area of the cast-in-place floor slab of the frame structure. The plate surface that bears negative bending moments should be pasted with steel plates or fiber cloth, which should be bent and anchored on the outer side of the edge beam and meet the anchoring length requirements.

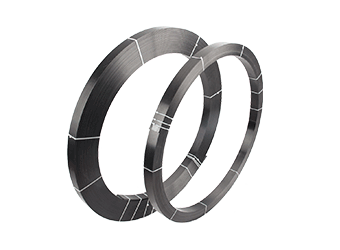

1. Bonding steel plate reinforcement method

For the bonded steel plate reinforcement method (referred to as the bonded steel plate method), the steel plate in the less stressed direction should be pasted on the inner layer (first pasted), and the steel plate in the more stressed direction should be pasted on the outermost layer (last pasted). At this point, the first adhesive steel plate should be slotted at the concrete surface, with a depth of ≥ steel plate thickness+3mm, to ensure that the surface of the first adhesive steel plate is flush with the bottom surface of the floor slab, or can be pasted in both directions. However, the steel plate in the direction of less stress needs to be cut into three sections, welded on site, and locally coated with adhesive.

The steel bonding method is applicable to general bending and tensile components that withstand static forces. The usage environment temperature should not exceed 5-60 ℃, the relative humidity should not exceed 70%, and there should be no chemical corrosion under the usage conditions. Otherwise, effective protective measures should be taken. When the strength grade of the component concrete is lower than C15, this method should not be used for reinforcement.

Related requirements:

a. The steel plate should be selected with a width of 100mm~200mm and a thickness of 3mm~5mm.

b. This reinforcement method can only be used for structural reinforcement with small openings. The floor has a small opening, which has a small impact on the stress of the board. This method can only be used for structural reinforcement.

c. The area of the compensating steel plate shall not be less than 1.2 times the equivalent cross-sectional area of the truncated steel bar

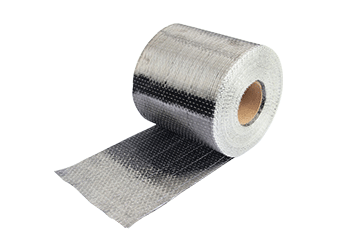

2. Reinforcement method using carbon fiber cloth

The reinforcement method of pasting carbon fiber cloth is also a type of compensation reinforcement method. This article mainly takes pasting carbon fiber cloth as an example to explain. When the opening position of the cast-in-place continuous slab is located in the negative bending moment area of the slab, double-sided reinforcement should also be carried out when pasting carbon fiber cloth for reinforcement. The order of pasting carbon fiber cloth vertically and horizontally can be unrestricted.

Compared with traditional methods such as increasing the concrete section or sticking steel, the method of pasting carbon fiber cloth reinforcement has the advantages of space saving, simple construction, no need for on-site fixed facilities, basically no increase in structural size and self weight, good corrosion resistance, and durability.

Related requirements:

a. The carbon cloth is selected with a width of 200mm~300mm and a mass of 200g~300g.

b. This reinforcement method can only be used for structural reinforcement with small openings.

c. The maximum tensile force of the compensating carbon cloth shall not be less than 1.2 times the equivalent tensile force of the truncated steel bar.

d. When the carbon cloth comes into contact with the steel plate, a layer of adhesive should be applied, and direct contact is not allowed.

e. Reliable anchoring measures should be taken at both ends of the fiber cloth, usually by pasting steel plate pressure strips.

When using the reinforcement method of pasting steel plates and pasting fiber cloth, it is necessary to note that when opening holes in the negative bending moment area of the board, the upper and lower parts of the board should be reinforced with double-sided reinforcement, and the anchoring measures at the ends should be ensured. At the same time, attention should be paid to unloading treatment, and the live loads borne by the reinforced components, such as personnel and office equipment, should be temporarily removed, and temporary construction loads should be minimized as much as possible.

Adding support beam method

When the opening of the floor slab further expands, resulting in a width b>1000 mm or D>1000 mm perpendicular to the direction of the slab's stress, or when the number of cut steel bars is>20%, or there is a large concentrated load at the edge of the opening, as well as when the prefabricated slab cuts off the main rib, additional edge beams should be installed at the edge of the opening to support and transmit force. Generally, the method of adding support beams is adopted, including the addition of steel beams or cast-in-place concrete beams. The addition of beams and floor slabs, as well as supporting structures (shear walls, frame beams, columns, etc.) should have reliable anchoring.

01 Add profile steel beams

When adding steel beams for reinforcement, H-shaped steel, channel steel, I-shaped steel, or composite steel can be used. The commonly used span to height ratio is 14-22, and the steel specifications are determined based on calculations.

After adding steel beams, it is necessary to review the bearing capacity of the floor slab under the new structural system. The floor slab and the newly added beam support are simplified as simply supported or fixed according to the actual situation. After the steel beam is wedged tightly with the floor slab, pour adhesive or high-strength cement slurry.

The connection between steel beams is made using ordinary bolts or high-strength bolts. The 5-5 profile and C-C profile show the connection between the steel beam and the shear wall. The anchor plate can be fixed to the shear wall using chemical bolts or expansion bolts, or connected through the wall screw according to the diagram. The connecting plate is welded to the anchor plate, with a thickness of no less than 10mm. The connecting plate is connected to the steel beam using ordinary bolts (or high-strength bolts) to achieve the connection between the steel beam and the shear wall.

02 Add concrete edge beams

When the span of the slab is less than 6m, additional concrete beams can be used to reinforce the opening of the slab, but the bearing capacity of the structural system slab needs to be rechecked and changed. At the same time, whether the original longitudinal and transverse frame beams need reinforcement should be determined by calculation. The support structure of the newly added beam should ensure the effective transmission of shear force.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Two-component epoxy modified epoxy structural strengthening adhesive for bonded steel plate to concrete