Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How is Carbon Fiber Plate/Laminate/Strip Produced?

On the professional pultrusion production line, the carbon fiber raw yarn is being led out through the guide device and enters the resin impregnation tank, where the viscosity, temperature and impregnation time of the resin are precisely controlled to ensure that the carbon fiber filaments are fully impregnated.

Then, the impregnated carbon fiber and resin pass through the heating mold to make the resin undergo a curing reaction to form a strong carbon fiber composite material. The heating process is divided into preheating zone, curing zone and constant temperature zone. The temperature control of different zones is crucial to the quality of the carbon fiber plate.

During the curing process, the carbon fiber composite material is stretched to the desired width and thickness through a traction device. The control of traction speed and stretching force will also affect the performance and quality of the product.

The stretched carbon fiber laminate passes through a rolling and cutting device to form a finished carbon fiber plate waiting to be shipped out from the warehouse.

Video:

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

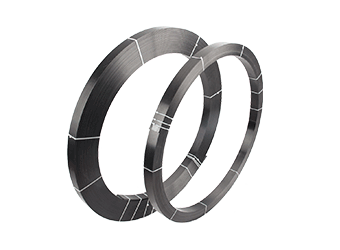

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength carbon fiber reinforced polymer plate adhesive for applying CFRP laminate/strip/plate on the structural members