Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Post Tension FRP System: A New Method for Strengthening Concrete Bridges

The aging infrastructure of bridges worldwide necessitates innovative and efficient strengthening techniques to enhance their load-bearing capacity and extend their service life. Among the emerging solutions, the Post Tension CFRP System has gained significant attention as a cutting-edge method for reinforcing concrete bridges. This advanced technology combines the high tensile strength of CFRP with the benefits of prestressing, offering a lightweight, durable, and corrosion-resistant alternative to traditional steel reinforcement.

Challenges in Conventional Bridge Strengthening

Traditional methods for strengthening concrete bridges, such as external steel plate bonding or concrete jacketing, present several limitations:

Corrosion susceptibility of steel leads to long-term durability issues.

Heavy weight increases dead load, requiring additional structural support.

Labor-intensive installation results in prolonged construction time and traffic disruptions.

These challenges have driven the development of advanced composite materials like CFRP, which offer superior mechanical properties and resistance to environmental degradation.

What is the Post Tension CFRP System?

The Post Tension CFRP System is an advanced structural strengthening technique where high-strength carbon fiber-reinforced polymer (CFRP) plates are tensioned (prestressed) and bonded to the tension zones of concrete bridge girders. This method enhances the bridge’s load-carrying capacity by introducing compressive stresses that counteract tensile stresses, thereby reducing crack formation and improving structural performance.

Key Components:

CFRP Plates:

Lightweight, high-tensile-strength carbon fiber strips (typically 1.2–1.4 mm thick).

Material Composition: High-strength carbon fibers embedded in epoxy resin matrix

Tensile Strength: ≥2800 MPa (compared to 400-500 MPa for typical steel reinforcement)

Elastic Modulus: ≥165 GPa

Thickness Options: 1.2mm, 1.4mm, and 2.0mm standard thicknesses

Width Options: 50mm, 100mm, and 150mm standard widths

Density: 1.6 g/cm³ (about 1/5 the weight of equivalent steel plates)

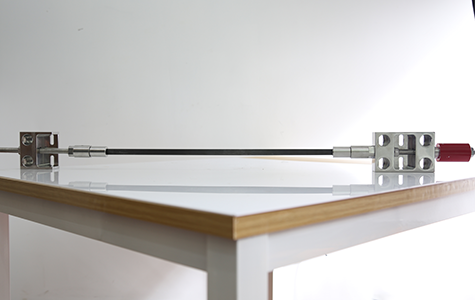

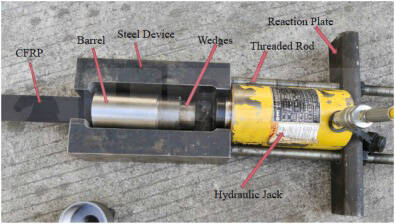

Prestressing Anchors:

Mechanical or adhesive systems that apply and maintain tension.

Tensioning Anchors: Hydraulic jacks capable of applying up to 600 kN of prestressing force

Permanent Anchors: Corrosion-resistant alloy steel components with load capacity matching CFRP strength

Load Transfer Elements: Specially designed clamping devices to ensure uniform stress distribution

Structural Adhesive:

High-performance epoxy resin for bonding CFRP to concrete.

Two-component epoxy adhesive with these key properties:

Tensile strength: ≥30 MPa

Shear strength: ≥18 MPa

Elongation at break: ≥1.5%

Operating temperature range: -40°C to +80°C

Why is This Method Superior to Traditional Techniques?

Limitations of Conventional Strengthening Methods

Method | Disadvantages |

External Steel Plating | Heavy, prone to corrosion, requires frequent maintenance |

Concrete Jacketing | Adds significant dead load, time-consuming installation |

Non-Prestressed CFRP | Limited effectiveness in crack control, lower load capacity improvement |

Advantages of Post tension CFRP Plate System

Higher Strength & Stiffness – CFRP has a tensile strength 5–10 times greater than steel at a fraction of the weight.

Corrosion Resistance – Unlike steel, CFRP does not rust, reducing long-term maintenance costs.

Minimal Weight Addition – Does not significantly increase the bridge’s dead load.

Prestressing Effect – Actively counteracts tensile stresses, delaying crack formation.

Fast Installation – Can be applied with minimal traffic disruption.

Long Service Life – CFRP has excellent fatigue resistance, ensuring durability under cyclic loads.

Performance Advantages and Technical Benefits

Structural Performance Metrics

Parameter | Improvement |

Flexural Capacity | +40-60% |

Crack Control | 70-90% reduction |

Fatigue Life | 3-5x extension |

Deflection Control | 30-50% reduction |

Long-Term Durability Features

Corrosion Resistance: Zero corrosion loss over 100+ year service life

Creep Behavior: <0.5% strain under sustained load after 50 years

Environmental Resistance: UV-stable coating maintains 95% strength after 30 years exposure

Fire Performance: 2-hour fire rating with intumescent coating option

Future Developments and Research Directions

Smart CFRP Laminates: Integration of optical fiber sensors for real-time structural health monitoring

Automated Installation: Robotic application systems for improved precision and speed

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength carbon fiber reinforced polymer plate adhesive for applying CFRP laminate/strip/plate on the structural members