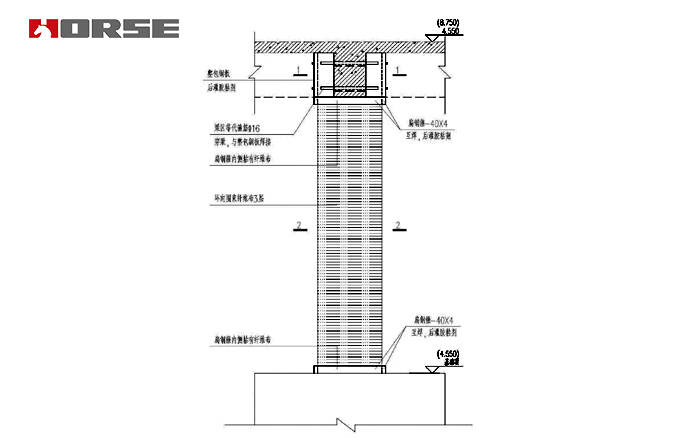

Column strengthening

CFRP and steel plate strengthening

The column reinforcement method was three layers of CFRP wrap, and the column beam was strengthened by steel jacketing.

Project overview

This project is the "Hefei city library function hall renovation project, located in the northern city of Hefei City Center District, village of amber villa entrance, the library of Southwest close amber villa residential area, south of the dam lake, north of the South Feihe river.

The repair and renovation of the construction area of about 1250 square meters. A total of five columns were reinforced, the elevation was strengthened from the base top to the elevation of 8.75 meters. The column reinforcement method was three layers of CFRP wrap, and the column beam was strengthed by steel jacketing.

Reinforcement material

1, The carbon fiber fabric with 300g/ square meters, the calculated thickness is 0.167mm, the tensile strength standard value of not less than 3400MPa, the tensile elastic modulus is not less than 240000MPa, elongation of not less than 1.7%.

2, Carbon fiber cloth should be glued together with glue and A grade glue. The relevant indicators should comply with the relevant provisions of 4.5.3 in GB50367-2013 code for reinforcement design of concrete structures.

3, Carbon fiber cloth requires a factory certificate, the bottom resin, leveling material, impregnating resin must be the same manufacturer and according to the manufacturer's requirements.

4, Structural adhesive for steel jacketing

5, Welding rod: Q235 steel, E43 series, Q345 steel, E50 series.

6. The type steel is Q235B steel, and the plate is Q345B steel.

7, The steel is HPB300 grade steel, HRB335 grade steel and HRB400 grade steel.

Reinforcement method

1, the frame column (JGZ) of the project should be strengthened with the CFRP wrap. The four angle protection layer of the frame column should be chiseled and polished into fillet, and the radius of roundness should not be less than 25mm.

2, the lap width between the upper and lower girth of the circumferential girth should not be less than 50mm, and the extension length of the fiber cloth ring truncation point should not be less than 20mm. The lapping positions of the strips should be staggered, and the direction of the fiber fabric should be perpendicular to the longitudinal axis of the column.

3. The hole in the beam area should be anchored by adhesive.

4, the flat steel hoop, the equal generation of stirrup welded after the completion of the sticky fiber cloth.