Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Fiber Reinforced Polymer Composite(FRP) Jacketing; Reinforced Concrete Jacketing; Steel Jacketing

Jacketing is one of the most frequently & popularly techniques used to strengthen reinforced concrete (RC) elements, like

1.Columns.

2.Beams

3.Beam-column junction

The most common types of jackets are:fiber reinforced polymer comosite(FRP) jacketing;reinforced concrete jacketing;steel jacketing

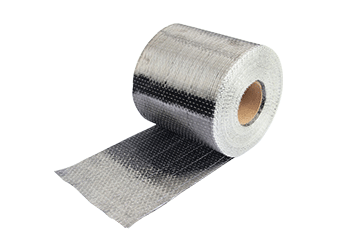

1.Fiber Reinforced Polymer Composite(FRP) Jacketing

jacketing with high tension materials like carbon fiber

2.Reinforced Concrete Jacketing

jacketing with high strength material like anchoring adhesive

3.Steel Jacketing

jacketing with materiasl like steel plate and structural strengthening epoxy

The main purposes of jacketing are:

1.To increase concrete confinement by transverse fiber reinforcement, especially for circular cross-section columns.

2.To increase shear strength by transverse fiber reinforcement.

3.To increase flexural strength by longitudinal fiber reinforcement provided.

Because of jacketing, enhancing axial strength, bending strength, and stiffness of the original column.

FRP jacketing is a developed technique to increase the strength and ductility of damaged or under-designed reinforced concrete structures.

column strengthening

beam strengthening

Reinforced concrete jacketing can be employed as a repair or strengthening scheme. Damaged regions of the existing members should be repaired prior to their jacketing.

column strengthening

beam strengthening

Local strengthening of columns has been frequently accomplished by jacketing with steel plates.

column strengthening

beam strengthening

| Steel Jacketing | Reinforced Concrete Jacketing | FRP Jacketing |

high corrosion | medium corrosion | corrosion resitstance |

| low cost | medium cost | medium cost |

| medium installation cost | medium installation cost | ease of installation |

| more maintenance | more maintenance | less maitanance |

| heavy weight | heavy weight | light weight |

Jacketing of columns:

jacketing of columns consists of added concrete with longitudinal and transverse reinforcement around the existing columns. This type of strengthening improves the axial and shear strength of columns while the flexural strength of column and strength of the beam-column joints remain the same. It is also observed that the jacketing of columns is not successful for improving the ductility. A major advantage of column jacketing is that it improves the lateral load capacity of the building in a reasonably uniform and distributed way and hence avoiding the concentration of stiffness as in the case of shear walls. This is how major strengthening of foundations may be avoided. In addition the original function of the building can be maintained, as there are no major changes in the original geometry of the building with this technique. The jacketing of columns is generally carried out by two methods

Beam jacketing:

Jacketing of beams is recommended for several purposes as it gives continuity to the column sand increases the strength and stiffness of the structure. While jacketing a beam, its flexural resistance must be carefully computed to avoid the creation of a strong beam-weak column system. In the retrofitted structure, there is a strong possibility of change of mode of failure and redistribution of forces as a result of jacketing of column, which may consequently causes beam hinging. The location of the beam critical section and the participation of the existing reinforcement should be taken into consideration. Jacketing of beam may be carried out under different ways, the most common are one-sided jackets or 3- and 4-sided jackets. At several occasions, the slab has been perforated to allow the ties to go through and to enable the casting of concrete. The beam should be jacketed through its whole length. The reinforcement has also been added ti increase beam flexural capacity moderately and to produce high joint shear stresses. Top bars crossing the orthogonal beams are put through holes and the bottom bars have been placed under the soffit of the existing beams, at each side of the existing column. Beam transverse steel consists of sets of U-shaped ties fixed to the top jacketing bars and of inverted U-shaped ties placed through perforations in the slab, closely spaced ties have been placed near the joint region where beam hinging is expected to occur.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement