Bonded Steel Reinforcement in Water Conservancy

Application of Bonded Steel Reinforcement in Water Conservancy Project Construction

Zhelin Reservoir's hoisting gear room middle frame cross beam and side beam bonded steel reinforcement construction ended in October 2016, with a total investment of about 798,000 yuan, which saves about 24% of the cost of traditional consolidation technology.

Project Overview

Zhelin Reservoir is the reservoir with the largest storage capacity of earth dams among the reservoirs built in China, and it is a multi-year regulating river reservoir. Zhelin Reservoir is composed of earth dam, spillway, hydropower station, water intake, etc. Due to the improvement of its design standards, the tensile strength of the surface tension area of the frame beams and side frame beams of the gate hoist room is difficult to meet the design requirements after rechecking, and must be reinforced. And it mainly adopts the structure sticking steel reinforcement technology that sticks steel plate on the surface of the tension area of the frame beam to achieve the purpose of auxiliary tension and reinforcement.

Engineering reinforcement requirements

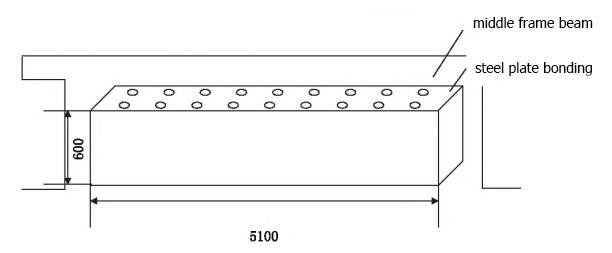

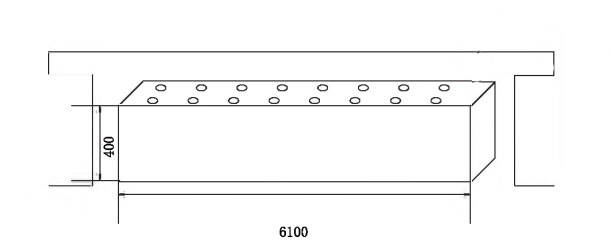

The components to be reinforced in the Zhelin Reservoir project include three parts: the middle frame beam of the gate hoist, the east side frame beam and the west side frame beam. Both the middle frame beams and the east-west side frame beams are reinforced by pasting reinforced steel plates above the beams and frame beams. The size of the reinforced steel plate adhered to the middle frame beam is 5100mmX600mm, 18 holes are arranged, the diameter of the holes is 150mm, the horizontal spacing of the holes is 416.67mm, and the vertical spacing of the holes is 150mm. The size of the reinforced steel plate pasted on the east and west side frame beams is 6100mmX400mm, 16 holes are arranged, the diameter of the holes is 100mm, the horizontal spacing of the holes is 662.5mm, and the vertical spacing is 100mm. The structure of the members to be reinforced, the reinforcement positions and the layout of holes are shown in Figure 1~Figure 2.

Construction process of glued steel plate

(1) Treatment of the bonding surface of the reinforced beam

(2) Steel plate fixing, installation and sealing of injection seat

(3) Inject liquid adhesive

(4) Health and maintenance

Concluding remarks

Zhelin Reservoir's hoisting gear room middle frame cross beam and side beam bonded steel reinforcement construction ended in October 2016, with a total investment of about 798,000 yuan, which saves about 24% of the cost of traditional consolidation technology. The stick-steel reinforcement construction did not adversely affect the normal water delivery of the reservoir, and the irrigation of 120,000 hm2 of arable land in the reservoir irrigation area was also carried out as scheduled.

The operation of the Zhelin Reservoir after the sticking steel reinforcement construction fully shows that the reinforcement of the middle and frame beams of the hoist room of the reservoir is correct. The used bonding steel reinforcement technology and the thick paste coating anti-corrosion comprehensive reinforcement treatment have strong applicability and technical safety, and the quality control measures are appropriate. It is of great significance for extending the service life of Zhelin Reservoir and improving the economic and social benefits of project investment.